Thin-walled glassware engraving still needs the S9 UV laser to play an important role

Website: http://www.rfhtech.com

Whatsapp(Wechat): 18928466502

Email: export06@rfhlasertech.com

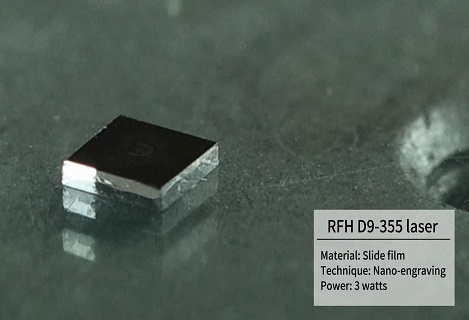

Both UV lasers and CO2 lasers can be used for glass engraving, but if it is used for laser engraving of thick-walled large-format glassware, in most cases, the high-power CO2 laser will be selected. In front of thin-walled glassware such as wine glasses, the RFH 355nm UV laser is a more suitable solution, because its wavelength is 355nm, the power range is 3w-20w, the precision focusing spot is extremely small, and the processing heat affected zone is small, it will not produce The thermal effect will not cause the problem of material burning, the processing quality is higher, and the perfect engraving of glass can be achieved.

What is the difference between UV laser and CO2 laser when engraving glass

How does glass laser engraving work?

In fact laser etching glass is very easy. During the glass laser engraving process, the material is directly etched. Unlike sandblasting, laser engraving only needs to design the desired marking pattern on the computer, convert the laser to laser, place the glass and start engraving.

What is the effect of glass laser engraving?

Etch the glass surface with a fine laser beam to engrave detailed photos, text and logos.

355nm UV laser is different from CO2 when engraving glass

Therefore, in addition to coarser glass engraving with CO2 lasers, more industrial users require finer, higher-definition engraving processes. This can be achieved with the RFH S9 UV laser. 355nm wavelength, small thermal influence, cold light source characteristics can engrave glassware more precisely and controllably.

uv laser | green laser | Ultraviolet lasers | uv dpss laser | nanosecond laser | UV laser source | Solid State Lasers