RFH high power UV laser should be used for metal stripping of electronic components

Sep 01 , 2022RFH high power UV laser should be used for metal stripping of electronic components

Never Stopping Progress, RFH High Power UV Laser Cleans Electronic Components Metal Stripping

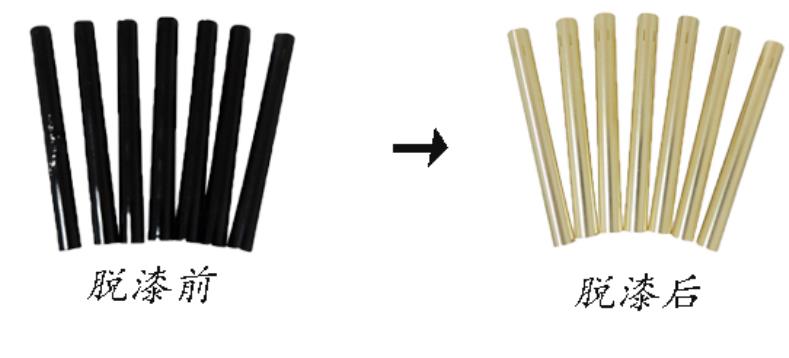

It is a very important process to coat the insulating layer on the surface of electronic components (such as inductance coils). As the basic electronic components, although the structure is simple, part of the insulating layer needs to be removed in the final step of the final product.

It is the last step of "peeling paint", which requires extremely high processing accuracy, as the so-called "painting is easy, peeling is difficult".

Faced with larger parts, we often used chemical and physical methods in the past. The chemical method is naturally a "paint remover", while the physical method is divided into two types: fire and mechanical paint stripping.

But no matter which one, it is almost impossible to accurately strip paint in the face of a device such as an inductor with a diameter of only a few millimeters.

However, with the advancement of technology, the non-contact method of laser has obviously replaced the old traditional paint stripping. Even in the face of tiny coils on electronic products such as mobile phones, laptops, cameras, etc., it can still be easily dealt with.

RFH laser uses 20W high-power ultraviolet laser to shorten the processing time to seconds. While exponentially increasing the processing speed, it reduces the heat-affected area, the edges are clearly visible, and the component substrate is not damaged. It is already the best choice today.

Its working principle is to use a high-energy density laser generated by a focused beam to quickly swipe across the surface to be stripped, so that the surface coating instantly melts and vaporizes to achieve the purpose of precise stripping.

After more than 15 years of dedicated research and development, RFH has continuously made breakthroughs in the field of lasers, and launched the Expert III 355 high-power UV pulsed solid-state laser.

Expert III 355 High Power UV Pulsed Solid State Laser: High Power Five-Star Recommendation

RFH Expert III 355 series UV solid-state laser adopts unique laser cavity design, acousto-optic Q-switching technology, and high-precision cooling system, small size and high integration.

The unique Q-switching control technology is suitable for various laser application control needs. At the same time, the inner cavity self-purification system is added to make the laser have a long life and stable operation.

In terms of precision performance, RFH Expert III 355 can achieve "±0.02mm high precision". The reason why it can achieve this level is mainly because of its superior beam quality (M2<1.2), and it is strictly guaranteed in all frequency ranges. . As for another key factor affecting accuracy, the RFH Expert III 355 has a very short pulse width (<25ns@50k) and a small heat-affected area during processing, ensuring impeccable operation every time.

Whether the laser is stable will directly affect the final product. Under the control of RFH, no matter how precise the parts are processed, problems such as burning and deformation can be avoided, and the paint stripping speed is fast, accurate and stable.

As for efficiency, due to the wide application of electronic paint stripping, RFH adopts all-digital intelligent power control technology through the combination of software and hardware, which is easy to operate, convenient for monitoring, supports communication with computer, and can control the laser externally through RS232.

In the face of the industrial digital revolution, RFH has never neglected, and innovation has always been around. Under the tide of digitalization, it can greatly improve production efficiency and reduce post-operation and maintenance costs.

In the field of electronic processing, the application market of paint stripping will become more and more common with the development of science and technology. Today's electronic products are more and more integrated, and the demand for removing surface insulating layers will also increase year by year.

With RFH high power UV lasers, this has never been easier.