RFH 50W infrared laser cuts thin copper sheets, smooth edges, no burrs

Jan 03 , 2023RFH 50W infrared laser cuts thin copper sheets, smooth edges, no burrs

Copper is a commonly used material in our daily life, and has important applications in many machines and electronic devices. Copper sheets can conduct electricity, easy cut, and cheap to similar products. They are strong and plastic. They are the best manufacturing materials.

At present, the cutting of copper sheets has basically shifted from traditional cutting processes to modern cutting processes. RFH infrared laser is a good helper to auxiliary cut copper chips. It is a long -term verification, high -reliability, and all -weather product. It supports the power of maximum 60W at 1064nm wavelength, and 50W power used for copper chips is the most suitable power to study.

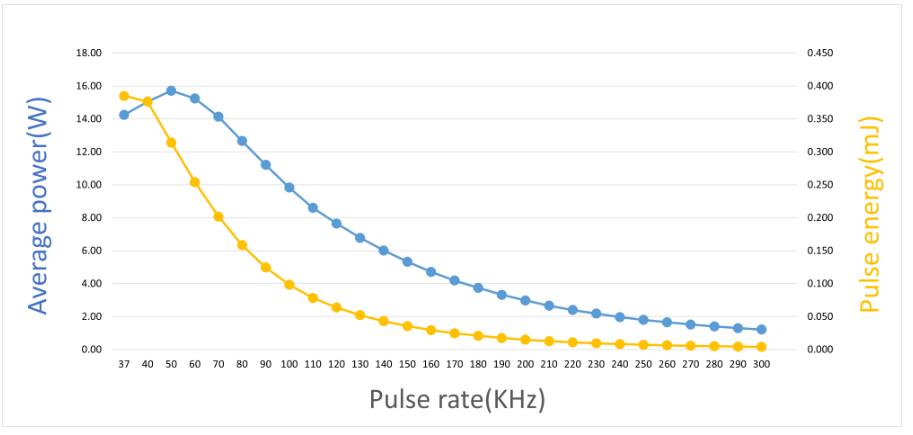

Of course, because RFH has pulse frequency division inside the machine, a variety of frequency functions can be achieved, and more functions and selectivity are available on the basis of solid durability.

Different from cutting consumables multiple times in traditional craftsmanship, RFH infrared laser is easy to install, and the accuracy reaches 0.02mm of the physical limit. In addition, RFH infrared laser will not generate any dust during use, which can ensure the environment in the process of use. Turnive and human health.

The infrared laser controlled by software continues to improve under the continuous improvement of RFH, adapting to the huge market and special status of copper cutting, and also occupy a position in the copper chip processing market to help more companies participate in production.