355nm Ultraviolet lasers excel in large area structuring and 3D micromachining

Dec 30 , 2022355nm Ultraviolet lasers excel in large area structuring and 3D micromachining. Advanced beam illumination and projection techniques allow for sharp-edged and uniform energy density distribution on target. This leads to fine control of the volume of material removed per pulse, enabling high-resolution machining and high-quality surface finish. Typical removal rates

What is 355nm Ultraviolet lasers: https://www.rfhtech.com/s9-y-integrated-uv-laser_c4

are between 0.05 - 1.5 μm/pulse. When a single pattern must be repeated, the mask itself may contain an array of features, using the large beam cross section for simultaneously machining multiple features. By coordinating the motion of both mask and workpiece, large and complex patterns can be created.

Polymer Micromilling

Galvanometer scanning combined with a high-speed pulsed laser enables definition of complex shapes. The microfluidic channel shown to the right is machined into a polycarbonate component.

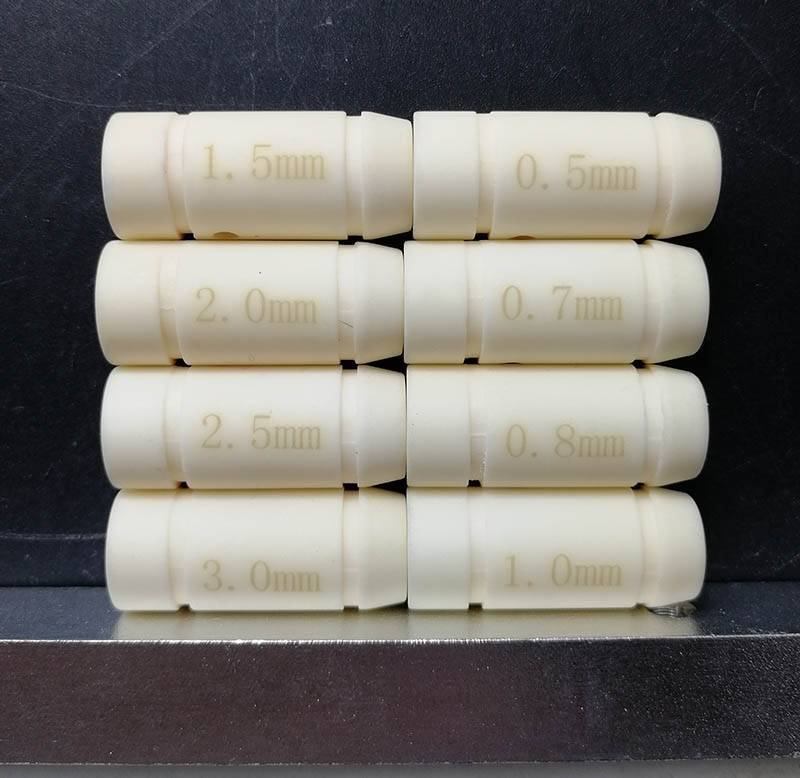

Our systems can perform ablative and thermal ceramic micromilling, cutting and scribing for materials up to 1 mm thickness with sub-micron feature placement and dimensional accuracy. Here we show precision grooves in ceramic cylinder.

Metal Micromilling

Example shows machining of grooves ~ 30 μm wide and deep on molybdenum plate using picosecond laser.