RFH 3w-10w air-cooled and water-cooled UV laser for 3D printing

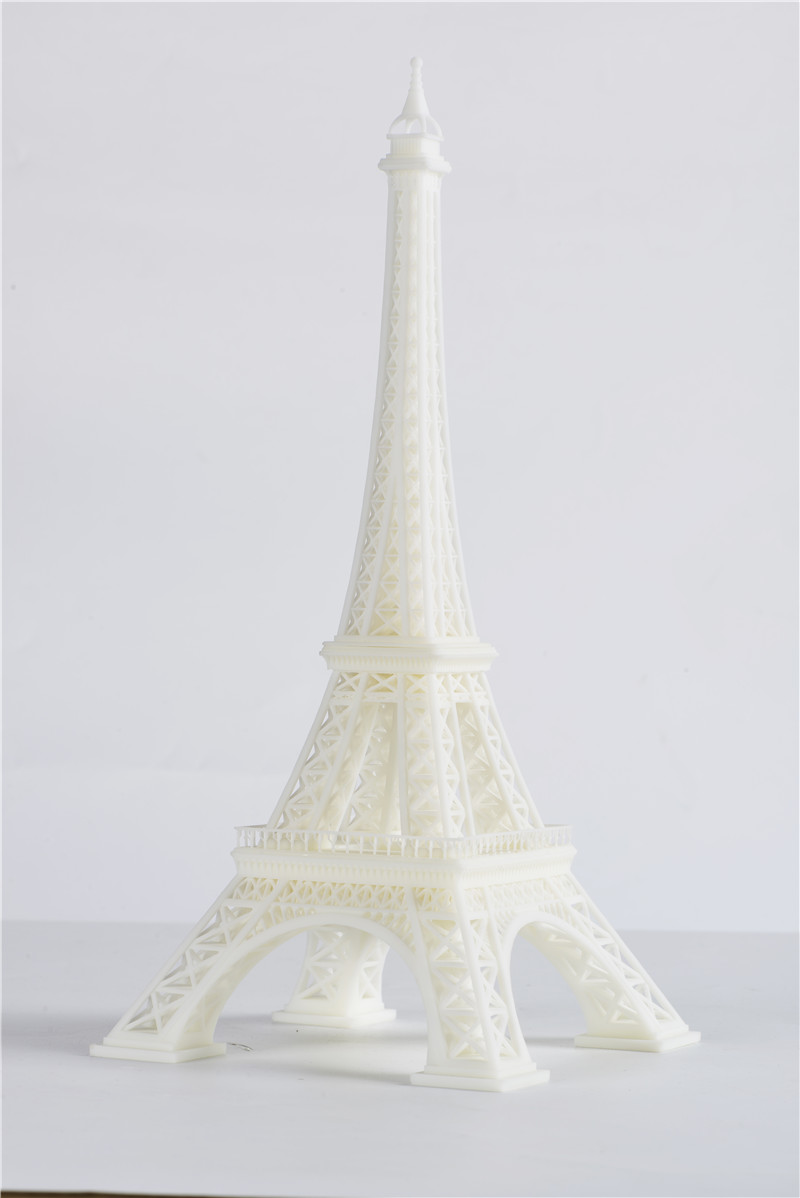

3D printing is a very important emerging technology in the current market. It deforms the resin and uses ultraviolet laser cold processing technology to control the shape of the resin, so as to realize on-demand customization services.

RFH's 3w-10w UV laser has recently made a new attempt in 3D printing, which is to upgrade the UV laser processing technology, so as to achieve high-speed, high-precision light curing effect. The RFH ultraviolet laser adopts non-contact production, which can use the direct light of the spot to deliver very high energy to the resin material, and convert it from light energy into heat energy, so as to make the resin solid-state.

Some people may worry that such an energy laser beam will affect the properties of the resin in the production process, but in fact, the 3D printing process will not cause any damage or burnt consequences under the projection of an ultraviolet laser whose thermal effect is basically zero, but It can ensure the smooth and flawless processing area.

In addition, the RFH ultraviolet laser adopts two designs of air-cooling and water-cooling, which can meet the different needs of different manufacturers and realize customized services. It has been upgraded and evolved in 3D printing, and the positioning system and precision monitoring system can be fully put into use. In stricter 3D printing production, it surpasses most similar products on the market.

The invention of 3D printing has optimized our production, making some whimsical handicrafts and processed products that are difficult to design and form a reality that can be easily realized. And RFH has been involved in this process and has become a laser technology product supported and loved by major customers.