PCB cutting board, engraving, all need to use green laser technology

At present, almost all electronic devices on the market use PCBs to carry electronic control hardware. Today, as the hardware of electronic products continues to shrink, more miniature PCB boards will occupy more markets, which also means that the cutting technology of PCB boards will face more severe tests.

Under such circumstances, how to strip the paint on the smaller PCB boards has become a problem that many manufacturers need to consider, and RFH has solved these problems one step ahead of the market, and has occupied an important position in the foreign PCB cutting market.

At present, RFH green lasers have entered many domestic electronics factories for PCB panel cutting and production, and have a very important market position in East Asia, Western Europe and many regions and countries in Africa.

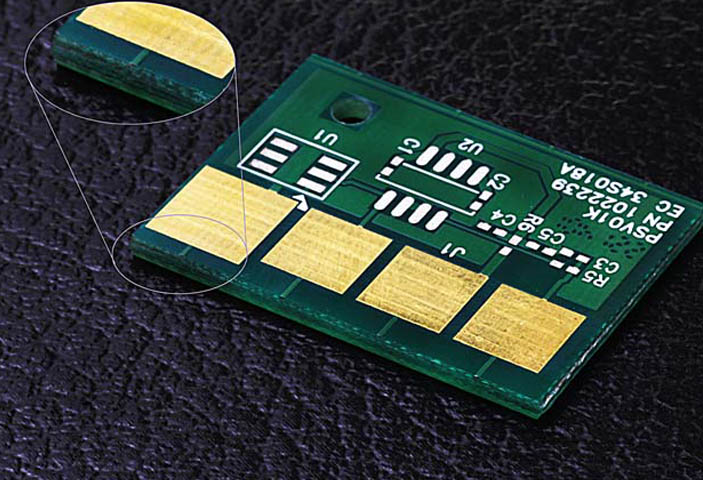

The RFH green laser can emit green light spots, quickly scratch the surface of the PCB, and cut the PCB panel through the high-energy laser beam.

Secondly, the RFH green laser has a high absorption rate for materials and can be used on a variety of materials with different components. For PCBs with complex components, it can cut well regardless of the composition ratio. RFH green laser can be used by plugging in. It is safe, environmentally friendly and reliable in use. The dust-free production method meets the strict environmental protection standards of foreign countries, and the simple operation also provides room for high labor costs abroad.

One thing that customers are very confident about is that RFH green lasers can also contract PCB marking, paint stripping, blackening, etc. One machine is multi-purpose, and it can help the production line to cut all the time. The RFH green laser meets the requirements of the domestic market and also meets the requirements of foreign production. With Chinese-made characters across the ocean, it has also achieved excellent development on the other side.