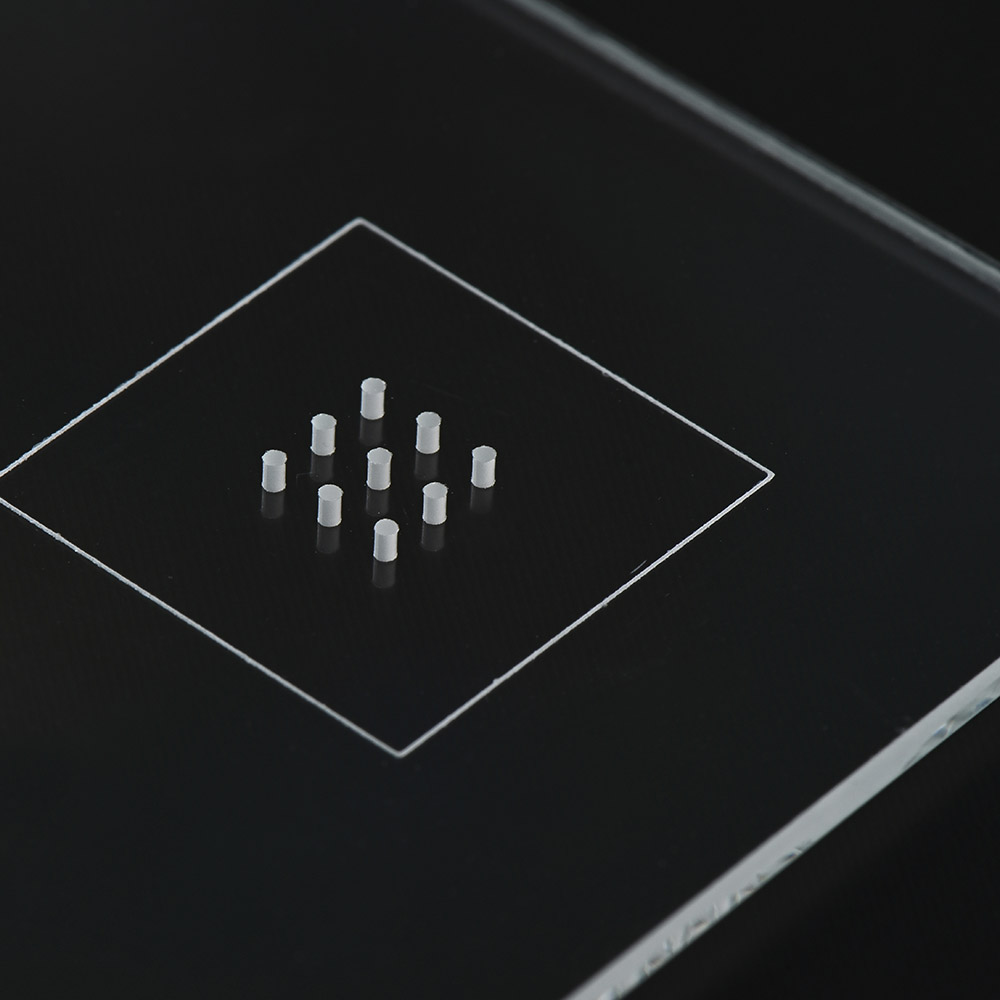

532nm green laser is used in laser drilling, marking and engraving of liquid crystal glass substrates

Liquid crystal substrate glass is a special glass material that is mainly used in the manufacture of liquid crystal displays. Liquid crystal displays are widely used in electronic products such as smartphones, tablet computers, televisions, computer monitors, etc. And its high transparency, good corrosion resistance, good heat resistance and other advantages also allow it to quickly occupy a favorable position in the market.

As a leading laser technology company, RFH green laser has noticed the outstanding characteristics of liquid crystal substrate glass a few years ago, and entered into many enterprises to help them in marking, engraving, cutting and other aspects of liquid crystal glass substrates. operate.

The production of liquid crystal glass substrates often requires in-depth processing. Under this kind of processing, the laser spot of RFH moves fast and the production efficiency is high. It can continuously improve the production speed and meet the production needs of customers.

Secondly, the production quality of RFH green lasers is extremely high. Almost all of the domestic leading liquid crystal glass substrates are produced by RFH, because RFH has strictly controlled the production accuracy to around 0.02mm, reaching the physical limit, fully satisfying major customers demand. In addition, the RFH green laser has its own positioning system, which can be used only by connecting to a computer, and can switch between multiple modes to complete various productions such as cutting, marking, and engraving. One machine with multiple functions is indeed a model.

RFH's efforts in the liquid crystal glass substrate industry over the years have been rewarded. Almost all liquid crystal glass substrates on the market have RFH's production or technical participation, which also proves that RFH is making continuous progress and is constantly walking in the forefront of laser technology. cutting edge.