355nm UV solid-state laser marking wood, low carbon and environmental protection

Wood is one of the earliest materials discovered and used by human beings. It is widely used and is an unreliable material and component in all walks of life. People also like and support wood carving more and more to participate in production and life. The wood stick rotary marking process can describe the required graphics on the rotating wooden stick and fully reflect the entire part, greatly surpassing the speed of wooden stick engraving in the past, and RFH is an expert in this process.

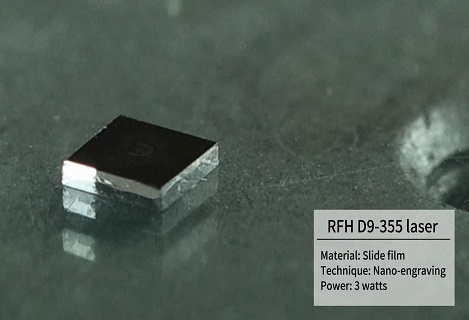

The RFH UV laser enables faster stick marking, saving the cost of buying another machine. At present, most of the stick marking methods used in the market are traditional ink marking methods, while UV laser engraving belongs to non-contact marking, which can quickly mark the surface of sticks and accurately control the accuracy of the surface , so that it is controlled within 0.02mm, and it is processed sharply.

The nanosecond UV laser with a repeat coverage of 200kHz can adapt to different wood properties. The integrated design facilitates its integration with other equipment. The small size can pass through the route without a huge optical path. The laser application is realized with Q-switching technology. Various needs on wooden sticks. Traditional ink marking often produces a lot of ink pollution, and is far inferior to laser marking in terms of marking accuracy and durability.

The application and innovation of RFH nano-ultraviolet lasers have been favored by many customers, and the various styles of stick marking are also sweeping the entire market. The modular design concept of RFH leads the national laser industry and brings a new look to the domestic laser industry.