Why is RFH nanosecond green laser suitable for engraving PCB board

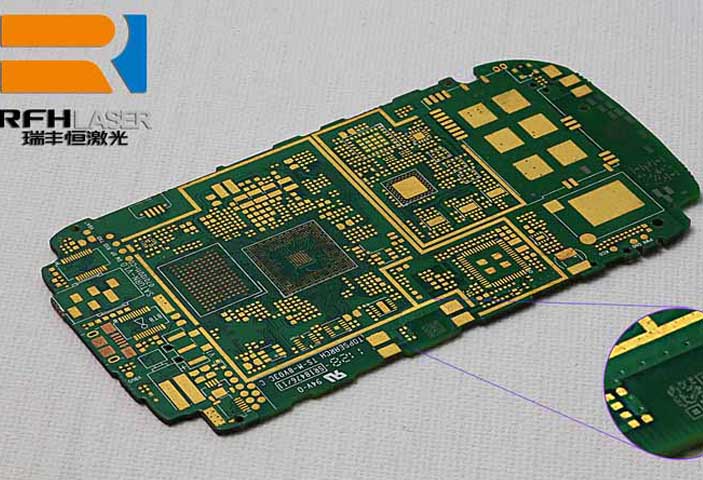

PCB board, also known as printing line board, is an important electronic component, a supporting body of electronic components, and a carrier for electronic components to connect to each other. Nowadays, many electronic devices are supported by PCB boards, creating software and hardware on it, and can be given to the PCB product information more clearly through the QR code.

How is the PCB board QR code engraved?

The RFH green light laser can print the QR code accurately on the surface of the PCB board through non -contact labeling, so that the printed text graphics can never be abrasion without any consumables.

Why is green laser suitable for carving PCB board

Expert III 532 Green Laser 35W:https://www.rfhtech.com/expert-iii-532-green-laser-35w_p16.html

1. The light spot emitted by the RFH green light laser is very small, and the thermal effect during the marking process is almost zero. Therefore, the high energy of the laser beam will not impact the material to scorch or be destroyed, and it will reduce the consumables.

2. The RFH green light laser occupies a small area and does not produce any pollution during the marking process. It is a completely green and environmentally friendly material. The marking speed is extremely fast. It is suitable for the production of the assembly line. efficiency.

3. In terms of configuration, RFH is equipped with high -speed high -quality digital scanning mirrors, and its performance has reached the international advanced level. The accuracy of about 0.2mm fully meets the current tiny PCB panel marking, making many manufacturers quite satisfied.

The advantages of RFH green light laser are obvious. Behind the orders reached are the trust and praise of digital manufacturers, and it is also the way to achieve the goal of the goal of first -line laser enterprises at home and abroad.