Why green lasers and UV lasers are recommended for cutting non-metallic PCB materials

Aug 21 , 2022Why green lasers and UV lasers are recommended for cutting non-metallic PCB materials

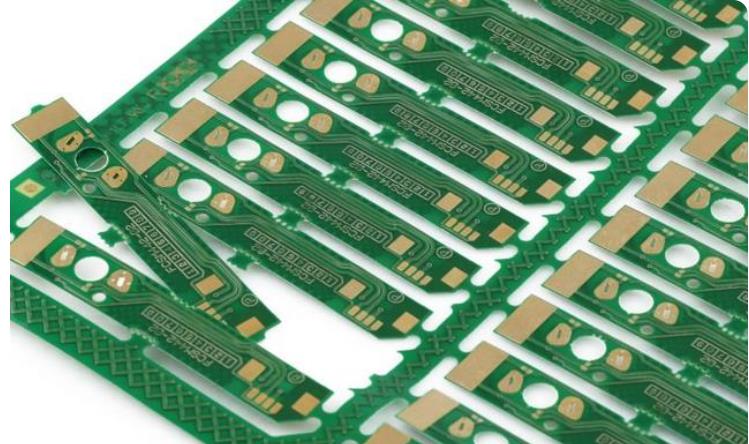

The application of laser cutting equipment is very broad. In the field of PCB sub-board, laser cutting is also a very mature product. He specializes in various precision cutting tasks, and the accuracy is often between millimeters. This is Not possible with traditional knives. Then many customers are also troubled when they choose, because the image given to us by the public is that the laser cutting machine is used to cut metal. Is it the same as the laser cutting machine for cutting PCB? In addition, what is the difference between fiber laser cutting and UV laser cutting machine and green laser cutting machine? What is the effect of different light sources of laser cutting machine on PCB sub-board?

1. Why can't a laser cutting machine for PCB be formed at one time like a metal cutting machine?

According to different materials, the optical mode of PCB laser cutting machine is different. For example, infrared fiber lasers are used when cutting aluminum, copper, and ceramic substrates. Like traditional metal laser cutting, it's a one-shot molding. Fixed focus mode is often referred to as straight focus. Ultraviolet or green laser is used to cut glass fiber cloth substrates, composite substrates, paper substrates, resin substrates and other materials, and the vibrator scanning mode scans and peels off layer by layer to form cutting.

2. What is the difference between optical fiber, green light and UV laser cutting PCB circuit board?

Infrared fiber laser cutting is mainly used for processing metal substrates and ceramic substrates. Green and UV laser cutting belongs to the category of semiconductor lasers and is used to process ultra-thin metal substrates and non-metal substrates.

Infrared fiber has more power and greater thermal impact. Green light is slightly better than fiber laser with less thermal effect. Ultraviolet laser is a processing method that destroys the molecular bonds of materials, with minimal thermal impact. It is also a non-metallic cutting PCB green light. There will be slight carbonization in the process of circuit board processing, while ultraviolet laser can achieve very small carbonization or even no carbonization at all. .

3. Why are green and UV lasers recommended for cutting non-metallic PCB materials?

Compared with milling cutters, gongs, walking knives, etc., the cost of laser cutting machines is high. Compared with milling cutters, gongs, walking knives, etc., the efficiency advantage is not large. In order to improve the competitiveness of PCBs, laser cutting machines are manufactured. On the other hand, 16 years ago, high-power UV lasers were more expensive, and there were no domestic high-power UV products. With the continuous development of laser technology, 15W with the above-mentioned high-power UV With the continuous development of lasers, domestic lasers have begun to increase their power, forcing foreign UV lasers to cut prices. With the decline in the price of UV lasers, more and more PCB laser cutting machine manufacturers have begun to launch high-power UV laser cutting machines, while the introduction of green laser cutting machines is relatively rare.

The main difference between UV laser cutting machine and green laser cutting machine lies in equipment cost, processing efficiency, processing effect and processing purpose. Ultraviolet laser cutting machine PCB can be considered to consider FPC soft board cutting, IC chip cutting and some ultra-thin metal cutting, while high-power green laser cutting machine is cutting PCB There is only one field that can only do PCB cutting hard board, in FPC soft board , Although IC chips can also be cut, the cutting effect is much lower than that of UV lasers. Compared with the UV laser cutting machine, the green laser cutting machine has a lower price and higher processing efficiency in the early stage. However, as the power of the UV laser cutting machine increases, this advantage gradually stabilizes. In terms of processing effect, because the UV laser cutting machine is a cold light source, the thermal effect is small and the effect is more ideal.

To sum up, the cutting of PCB circuit boards (non-metallic substrates, ceramic substrates) adopts vibrating mirror scanning mode to peel off layer by layer, and high-power ultraviolet laser cutting machine is used in the mainstream market of PCB.