Why do masks export abroad need UV laser marking for anti-counterfeiting

Jun 30 , 2021

As of now, more than 600,000 people have been diagnosed with new coronary pneumonia worldwide. As the epidemic spreads abroad, the business of masks going overseas is booming. After Italy announced the purchase of masks from China, the French company LV also announced an order for 40 million masks from China. Giants such as Foxconn, Sinopec, BYD, and Wuling have all used existing production lines to switch production of masks and plan to sell them overseas. Many small and medium-sized enterprises have also cross-boundary and joined the mask production army. According to the search results on Tianyan Check, there are as many as 65,811 companies with the word "mask" in the business scope.

However, going abroad for masks is not as simple as the merchants think, and the censorship of masks abroad is higher than that at home. In the European Union, masks are personal protective equipment, and all masks exported from the European Union must obtain a CE certification. Medical masks exported to the United States require FDA certification of related products and classification review of Amazon related product categories before they can be sold on shelves and solve logistics customs clearance issues.

Strict review has led to uneven masks in the market. Some companies have not completed the process in order to catch up with the construction period and directly leave the factory and sell them overseas as shoddy products. This seriously affects the interests of companies that strictly abide by European and American production standards. What's worse, with the surge in demand for masks abroad, the insufficient supply of masks has caused mask manufacturers to have a certain premium capacity. Inferior masks can be sold as good as high-quality masks. price. Anti-counterfeiting of masks has become an important means of distinguishing high-quality masks from low-quality masks, which has effectively improved the competitiveness of manufacturers in overseas markets.

Laser anti-counterfeiting helps masks go to sea

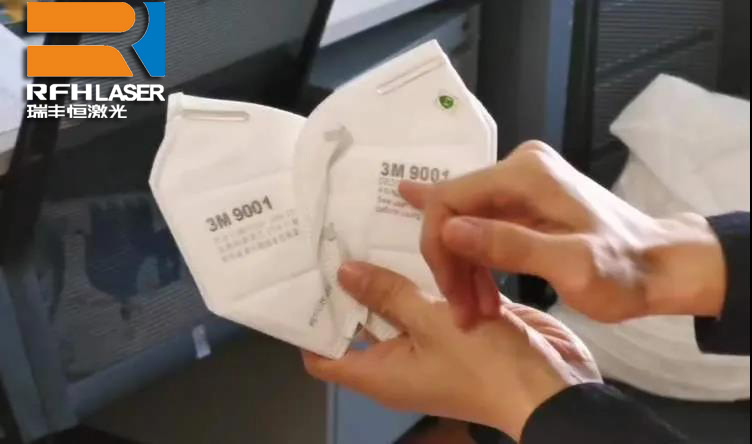

Overseas purchases attach great importance to the qualifications of masks. Many customers, regardless of the quality of the masks, directly ask whether they have a CE certificate or an FDA certificate. Due to long-term international transportation, certificates printed by traditional inkjets are easily damaged and blurred during transportation, resulting in insufficient recognition and causing customers to question. At this time, manufacturers can use laser printing to increase the authenticity anti-counterfeiting identification of the logo, parameters, and certificates of the mask. The laser-etched 3M masks never fall off the information, and the writing is clear and easy to read.

During the epidemic, Ruifengheng Laser's mask laser marking technology was also widely used in the anti-counterfeiting of genuine masks. Ruifengheng Laser uses Expert Ⅱ 355nm ultraviolet laser to emit high-energy laser beam. By controlling the path of the laser on the surface of the material, an identification code that never falls off is formed on the outer layer of the mask. Any syrup wipe will not work, and environmental protection is zero pollution. , To help the anti-counterfeiting of mask products and effectively improve the product competitiveness of manufacturers.

Advantages of laser marking anti-counterfeiting

Compared with traditional inkjet marking, the basic principle of laser marking is to use a high-energy-density laser beam to act on the surface of the material, and by controlling the path of the laser on the surface of the material, the required permanent graphic marks can be formed. Because laser marking can produce various characters, symbols and patterns, and the size of characters can range from millimeters to micrometers, this has special significance for the anti-counterfeiting of products, so it has a wide range of applications in the anti-counterfeiting market.

Laser marking anti-counterfeiting also has a wide range of uses in the medical equipment and pharmaceutical markets, such as common pills, soft capsules, and pharmaceutical packaging. If lithographic printing is used, it will put pressure on the product, while non-contact laser marking will not cause The product is deformed and the label falls off, and the tiny pill can be marked with more minute information, which is sterile and pollution-free.

Ruifengheng Laser is committed to high-quality mask laser marking anti-counterfeiting

After 13 years of development and precipitation, Ruifeng Heng Laser currently has a top laser research and development team composed of professors and experts at home and abroad. It has established an application process research and development department, a laser research and development department, and an electrical research and development department. It has technology patent certificates issued by many countries. Dozens of computer software copyright certificates have been awarded "National High-tech Enterprise", "Shenzhen High-tech Enterprise", "Software Enterprise Certification Certificate" and other certificates, and are awarded by Guangdong 3D Printing Industry Innovation Alliance and Guangdong Laser Industry Association Appointed as the governing unit.

In the context of the spread of the epidemic around the world, masks are a good opportunity for Chinese-made masks to establish a brand in the world, and the reputation of Chinese-made masks should not be damaged due to the overfilling of inferior masks. The use of laser marking and etching for anti-counterfeiting is not only responsible for its own products, but also responsible for the reputation of Chinese manufacturing.

Ruifengheng Laser will use the latest laser technology to promote the benign development of anti-counterfeiting masks, and play a more active role in public health through technical means.