The Advantages of high power UV Laser-Based PCB Cutting Depaneling

Feb 07 , 2023The Advantages of high power UV Laser-Based PCB Cutting Depaneling

Technological changes in the materials, thickness, and composition of PCBs are motivating a

move away from traditional mechanical cutting and depaneling methods towards laser-based

processes. But not all lasers for PCB depaneling are created equal. There are significant

differences amongst various lasers in cut characteristics and quality, specifically in terms of

heat affected zone (HAZ). This, in turn, affects process utilization since it determines how

closely circuits can be placed on a PCB, and can also impact circuit functionality and

downstream processes like waterproofing or EMI shielding. This document presents a new

nanosecond laser and associated cutting process developed at Coherent Inc. which enables

laser PCB depaneling with substantially reduced HAZ compared to other currently available

products.

The Evolving Need for Laser Depaneling

The continued market growth of miniaturized electronic devices, including smartphones,

various wearables, VR devices, automotive sensors, and home automation equipment, to name

just a few examples, translates directly into a need for denser, higher performance PCBs. Not

only are these devices physically smaller and more complex than the previous generation of

microelectronics, there is also a consumer demand for to make them more energy efficient (for

longer battery lifetime) and less expensive.

In terms of PCB technology, this has driven several trends. Amongst these are the use of

thinner traditional boards, wide scale implementation of flex circuitry, thicker conductive layers,

and increased utilization of low-κ dielectrics (the latter especially for 5G technology). Cost

considerations also prompt a need for improved process utilization. Specifically, this translates

into placing boards closer together on a panel to increase yield.

In terms of depaneling, all this necessitates increasingly narrow kerf widths and higher

dimensional accuracy for the cutting process. Closer physical proximity of the cut to the

functional areas of the PCB also means that the cutting process must not affect the

surrounding material or circuitry, whether due to mechanical stress or heat. Minimal

production of debris, which might require a subsequent cleaning step, is another requirement.

All these constraints make traditional mechanical PCB depaneling methods, including routers,

saws, die cutting, punching, scoring, and pizza cutting, etc., less practical and less cost effective.

This impels a move towards laser cutting which offers substantial benefits in virtually every one

of the areas previously mentioned, although usually at the expense of reduced cutting speed.

Understanding Laser Cutting

Laser depaneling has, of course, been in use for some time. However, it’s important to

understand and differentiate between the various laser-based technologies. The original

implementations utilized CO2 lasers which emit in the far infrared. This technology cuts by

heating the bulk material, which results in a significant HAZ. Also, compared with shorter UV

wavelengths, this long wavelength cannot be focused to as small a spot size, meaning a larger

kerf width.

Over a decade ago, the diode-pumped solid-state (DPSS), nanosecond pulsewidth, frequencytripled laser emerged as a viable source for PCB depaneling. It offers ultraviolet (355 nm)

output with sufficient pulse energy to enable material removal through a relatively “cold”

ablation process. That is, one with a much smaller (but still noticeable) HAZ than the CO2 laser,

and also substantially less production of debris and recast material. The pulse energy and

repetition rate of commercially available sources enable cutting at economically viable feed

rates, although not as fast as the CO2 laser. The primary benefits of this technology are

summarized in the table.

Table 1. Primary Characteristics and Advantages of UV Laser-Based PCB Cutting

While laser depaneling clearly delivers numerous benefits, PCB manufacturers are already

pushing this technology to the limits in order to meet the ever more stringent size, materials,

and cost challenges presented by the market forces mentioned at the outset. In particular,

achieving further reductions in HAZ and debris formation, and improving the cut quality

obtained with nanosecond pulsewidth UV DPSS lasers, is an active area of development.

To aid in this effort, applications research at Coherent Inc. has explored the outcomes and

process space of using a nanosecond pulsewidth, high pulse energy, UV DPSS laser (AVIA LX) for

cutting a variety of PCB materials and material combinations. Based on this work, the Coherent

team developed a new PCB cutting method that has already proven to deliver a reduced HAZ, a

higher quality cut edge, reduced kerf width, and increased production throughput.

One key element of this technique is a proprietary method for controlling the timing and spatial

positioning of laser pulses delivered to the work surface in such a manner that heat buildup is

avoided. Because thermal damage is absent in this approach, it’s possible to utilize a laser with

substantially higher pulse energy when cutting thicker materials (1 mm and above).

The advantage of higher pulse energy is that it eliminates the need to employ the traditional

scheme used for cutting thicker materials. Specifically, this involves making a series of laterally

displaced scribes to produce a “v-groove.” The “v-groove” geometry is necessary in order to

avoid clipping the beam as it penetrates farther into the material when making a high aspect

ratio cut. This would reduce its power, and thus limit ablation efficiency. However, the AVIA LX,

coupled with this novel pulse timing approach, can utilize pulse energies as high as ~400 μJ to

repeatedly scribe along the same line (no lateral displacement, or “v-groove”). The result is

faster cutting and significantly reduced kerf width.

Higher pulse energy also increases the laser focus tolerance at the work surface. Specifically,

when using a lower pulse energy laser, it is necessary to shift the focus of the beam as the

material is penetrated so that the minimum focused spot size is always maintained precisely at

the depth at which cutting is occurring. This is necessary in order to achieve sufficient laser

fluence to get above the material ablation threshold. However, doing this in practice requires

either physically shifting the PCB up, which slows the process, or employing a three-axis

scanner (one which has a focusing capability), which increases equipment cost and complexity.

The higher pulse energy of the AVIA LX makes it possible to simply focus the laser at a point

mid-way through the PCB and perform cutting. This is because there is sufficient laser fluence

for ablation even well out of perfect focus for the laser. The benefit is faster cutting, and

reduced system complexity.

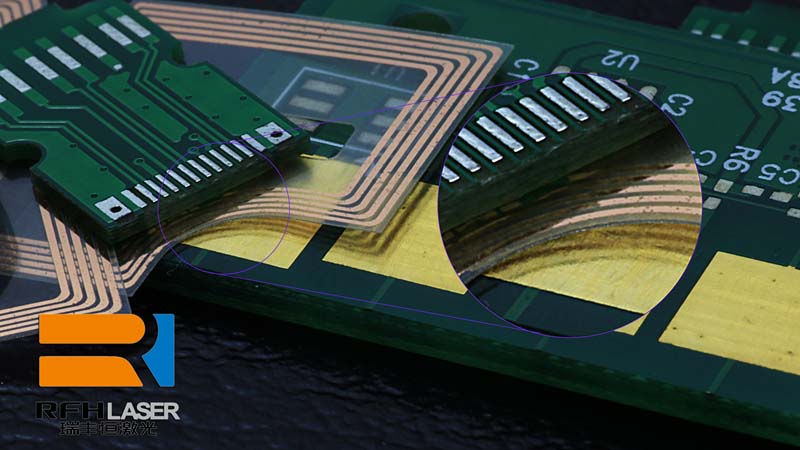

An example of the improvements are shown in the photos below, which compare cuts in a

1.6 mm thick PCB with copper traces, made using the type of UV DPSS laser currently

commercially available for this application versus the same material processed using the AVIA

LX and this new approach. The board processed with this technique shows a cleaner cut edge

and substantial improvement in the cut edges of the copper traces.

in the past, laser cutting of polyimide and EMI shield foil produced some delamination at the

cut line due to the wide HAZ. In this case, it’s necessary to use lower pulse energy in order to

avoid damaging the material. But, the same pulsing approach is utilized to eliminate heat

buildup, and delivers the same benefits of reduced HAZ and kerf width. This, in turn, reduces

production costs by enabling downstream production processes to achieve higher yields.

Practical, High Pulse Energy DPSS UV Lasers

For traditional thick PCB materials, implementing the Coherent pulse control method in

practice requires a UV DPSS laser source having higher pulse energy than previously

commercially available. To meet this need, Coherent developed the AVIA LX, a 20 W (at 355

nm), solid-state, nanosecond pulsewidth laser, which can produce a pulse energy of up to 500

μJ.

The AVIA LX lase was specifically designed to enable high throughput, high quality PCB

depaneling. It combines a number of technological advances in design and manufacture to

deliver this high energy output along with an unmatched combination of high reliability,

superior performance, and low cost of ownership.

AVIA LX leverages the extensive experience at Coherent in producing reliable, long lifetime

lasers with UV output. The non-linear (frequency tripling) crystals utilized in the AVIA LX are

produced within Coherent, giving us direct control over the quality and optical characteristics of

this critical component, and enabling us to achieve longer lifetime, improved performance and

reduced cost of ownership. Lifetime is further maximized by using a built-in crystal shifter

which contains a map of the actual crystal in the laser, and the location of 20 pre-qualified

third-harmonic generation spots (with over 1000 hours lifetime per spot) within it.

Contamination of the optics is a key limiting factor in the lifetime of UV lasers. AVIA LX lasers

are manufactured in a cleanroom, and the internal optics that are directly exposed to UV light

are contained within a PureUV sealed compartment to prevent contamination in actual use.

This maximizes lifetime and service intervals.

Furthermore, AVIA LX is based on an extremely robust industrial design, which has been

validated by HASS and HALT testing. In HALT (High Accelerated Life Testing), prototypes are

iteratively tested to destruction, re-designed and retested to eliminate any inherent

weaknesses. HASS (Highly Accelerated Stress Screening) then stresses actual production units

beyond their specified operating environment. This protocol screens out any deficiencies in

manufacturing and packaging. The result is unmatched product reliability and lifetime.

AVIA LX is also designed with ease-of-integration and ease-of-use in mind. For instance,

integration is simplified by using built-in control electronics, and an integrated beam expander.

The use of water cooling maximizes lifetime and pulse-to-pulse stability, even when operating

at high power.

In conclusion, the Coherent AVIA LX laser, together with novel pulse control technology, has

demonstrated superior results for PCB depaneling as compared to traditional mechanical

processes, and even previously available nanosecond pulsewidth UV DPSS laser sources. It

should prove a useful source for a variety of the fabrication processes required for next

generation microelectronic devices, including cutting of traditional PCBs and flex circuitry, SiP

cutting and trenching, and EMI shielding cutting.