The 355nm UV laser erases the text on the PCB circuit board, which is very convenient

Website: http://www.rfhtech.com

Whatsapp(Wechat): 18928466502

Email: export06@rfhlasertech.com

When producing PCB boards, the Metropolis will leave a lot of silk-screened text on the surface, which is mainly used to identify information such as circuit positions. However, in some cases, we need to clear these texts later, and it will be difficult to encounter finished PCBs. question.

If you use a UV laser to remove words on the PCB, it is no longer a difficult problem

Although clearing the text on the PCB silkscreen layer is a difficult problem, it is not completely helpless.

Here are a few common cleaning methods for you:

1 scrape with a knife

Advantages: Character processing is thorough.

Disadvantages: very destructive.

2 Override by new characters

Advantages: non-destructive.

Disadvantages: The part covered with text will become thicker, and there is a possibility that the previous text can be seen through light transmission.

3 redo solder mask and characters

Advantages: Character processing is thorough.

Disadvantage: There is a chance of scrap.

4 Potion cleaning

Advantages: Character processing is thorough.

Disadvantage: Cannot clear text precisely.

The above are the common methods for clearing text on the market today. They may not be complete, but they basically cover several major aspects.

In addition to engraving and cutting PCB boards, the 10w UV laser can also erase text

The main methods are nothing more than cleaning, scraping and covering, but through the experience summed up in practice, all methods have their own unavoidable problems, and the problem of low efficiency has not been mentioned here.

Since this demand has gradually become a rigid demand for many manufacturers, why not use a more advanced, low-cost, high-efficiency and low-risk method, that is, laser.

Different from all traditional methods of word removal, laser is a non-contact method, which has less impact on the board, and through simple programming, it can achieve many advantages such as more efficient, thorough text removal, and no damage to the board.

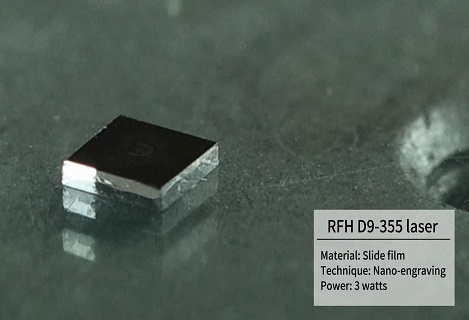

RFH Laser has been focusing on lasers for more than 15 years. It has the technical strength of independent research and development of power supplies, can better control the laser power, and has the ability to remove small text and patterns.

New flagship product - RFH S9 UV laser

As the latest flagship product of RFH, RFH S9 series UV lasers have the following advantages compared with similar products after 15 years of ingenious forging.

1 Small size and strong scalability

Different from the huge size of traditional lasers, RFH S9 UV laser saves more space due to its compact size, and does not need to enlarge the optical path. user cost.

2 Excellent beam quality

The RFH S9 UV laser has a power supply independently developed by RFH, the power control system is stable, and it has the ability to update the functional modules of the power control system in time. In addition, core components such as pumps and Q switches are also imported brands, with strict quality assurance from materials to procurement.

It is precisely because of such profound technical strength and strict quality control of parts that RFH S9 UV laser has superior beam quality (M²<1.2), which is strictly guaranteed in all frequency ranges; pulse width <12ns@30k, when processing The heat affected zone is small.

3 All-digital intelligent power control technology

In order to adjust the power parameters more precisely, the RFH S9 ultraviolet laser adopts a "full digital display" power control system, which supports external control of the laser through RS232, and remote communication through a computer to realize remote monitoring of the laser. The operation is simple and convenient.

Innovation is priceless, RFH moves forward

After years of technical tempering and accumulation, RFH has a strong R&D team composed of domestic and foreign professors, doctors and other high-precision professionals. The independent research and development of laser-specific power control systems leads the industry.

Whether it is strict quality control or the accumulation of experience and technology, these are the solid backing for the stable operation of the entire RFH laser system. Innovation is priceless, and RFH will continue to forge ahead!

uv laser | green laser | Ultraviolet lasers | uv dpss laser | nanosecond laser | UV laser source | Solid State Lasers