RFH Ultraviolet Laser 355nm is used for IC electronic PCB line board dating coding

Feb 14 , 2023RFH Ultraviolet Laser 355nm is used for IC electronic PCB line board dating coding

Unconsciously, the RFH laser spent a year with customers and friends. Along with 2020, there is a new era -5G era. 5G technology brings unlimited business opportunities to all walks of life, and the electronic component industry is one of them. With the arrival of the 5G era, the PCB for electronic communications will also usher in a great time -the number and value are increased.

In the future, the number of small base stations alone will reach 10 million. 5G base stations with higher speed frequency need to integrate larger area, higher -level PCB; the lightness of e -products such as 5G mobile phones and tablets that has been listed and will be fully popularized, driving the market space for FPC (a type of PCB) market space improvement ; Automotive electronics, electrification, and intelligence will also bring incremental market space to PCB.

The increase in the PCB market space has put forward higher requirements for the PCB manufacturing industry. Manufacturers must provide the market with better quality, longer service life, and better application benefits to the market at a faster speed. But how to ensure and identify this quality? Laser marking is one of the methods. Below, I will introduce the quality "appraiser" of a PCB line board -the RFH S9 355 series of ultraviolet laser.

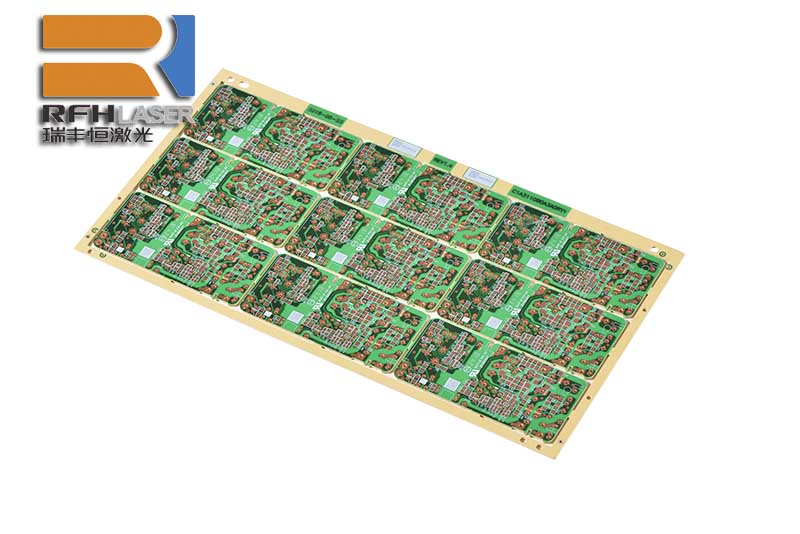

Using the RFH S9 355 series of ultraviolet lasers to mark information and patterns such as date, processing flow, QR code, etc. on the PCB line board, to record related production information to trace back and control the manufacturing of electronic products. Some people ask, the PCB circuit board material is so thin, how does the RFH laser ensure the label quality, whether the mark is clear, and will it burn the material? Xiaobian uses three aspects to tell you why RFH laser can ensure quality.

1. Super delicate laser

The RFH S9 355nm UV laser has superior beam quality (M2 <1.2), which is strictly guaranteed within all frequency range; the pulse width <20NS@30K, the heat affecting the area of the heat during processing is small, that is, not burning the materials; the perfect light spot Features (ellipse degree of light spots> 90%), so it can easily marked with fine and thin PCB line boards.

2. Doctoral R & D teams do technical backing

RFH Laser currently has a top laser R & D team consisting of professors, experts, and doctors at home and abroad (obtained 10 national patent certificates, 14 computer software copyright certificates). Electrical R & D department. The team independently develops power technology, which can update the power control system function module in a timely manner, and improve the functional module according to the needs of the laser. This is a solid backing for the stable operation of the entire RFH laser system.

3. RFH laser has a rigorous production quality management system

RFH laser from procurement and production of quality inspection and production, to assembly, finished products, and warehouse quality inspection, and then check before delivery. Strict control layers to ensure the consistency of quality stability and equipment parameters and actual operating parameters. Because of this, there are RFH laser with excellent performance and service life.

Because of quality, RFH ultraviolet laser is applied to PCB circuit boards. In the 5G era, RFH will further consolidate the excellent brand image in the laser processing industry.