RFH Solid Ultraviolet UV 355nm Laser Source Marking Plastic Cup

In terms of plastic marking, RFH can be said to be an expert for more than ten years. Since more than ten years ago, RFH has started to study how laser plastic marking can replace traditional marking methods, so that plastic marking can be guaranteed on the basis of greater quality. Increase speed and efficiency.

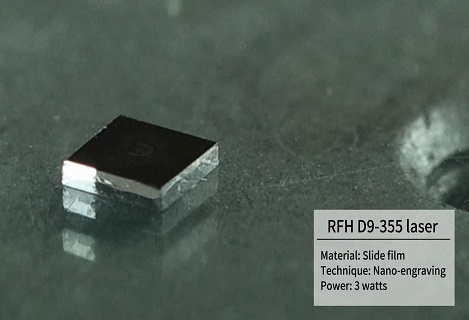

RFH Ultraviolet UV 355nm Laser Source is the result of RFH's continuous progress and innovation for many years. It emits a laser cold light source to carve on the plastic surface to obtain the required graphics and text. RFH Ultraviolet UV 355nm Laser Source can be connected with computer equipment, draw the desired graphics through software, and turn the drawings into reality through simple software settings.

It is worth mentioning that RFH Ultraviolet UV 355nm Laser Source can also maintain a minimum accuracy of 0.2mm when facing a curved plastic cup, and the graphics obtained by marking can never be erased during use, ensuring that the quality surpasses traditional ink markers.

In terms of speed improvement, RFH Ultraviolet UV 355nm Laser Source can maintain a stable output for 24 hours, and the marking speed is very fast. It only takes a few seconds to complete a pattern, and it can still ensure the integrity of the plastic without scorching under high-frequency pulses , is a good helper for flying plastic cup line marking.

RFH's development and research for more than ten years has won the favor and trust of many plastic customers. It is a famous name of the domestic leading laser enterprise. It will also continue to improve in the future and expand to broader fields and regions. Soil determination and strength.

Because the thermal effect of the RFH 355nm DPSS Ultraviolet Laser is almost zero, except for the established light transmittance, there will be no damage or burnt traces of other plastic parts. In addition to processing quality, the processing efficiency of the RFH 355nm DPSS Ultraviolet Laser also satisfies customers. 355NM DPSS Ultraviolet Laser can switch different modes for different plastic materials, and there are various processed forms such as marking, cutting, and punching. In addition to the stable operation of 24 hours, the peeling speed is extremely fast, which can meet a large number of orders. Require.

The RFH R & D team is composed of more than a do Ph.D. and professor of Tsinghua University. After more than ten years of efforts, the design ideas and operating trajectories of 355nm DPSS Ultraviolet Laser have made RFH a laser machine with advantages and capabilities in the market.

10w solid-state UV laser parameter:

Power supply+laser head+cooling system sold in a group

Being client-oriented, RFH offers proposal of selling the whole laser system in a group so that the laser system can maximize its performance while maintaining its stability.