The new generation S9 UV laser is specially designed for flying laser marking

RFH's new S9 UV laser is more stable and more scalable than similar products

RFH's new S9 UV laser is small in size, exquisite in design, and stable in light output

With the development of the global economy, the demand for industries centered on precision machining and intelligent manufacturing will also increase. In recent years, precision processing companies represented by RFH have achieved remarkable results in food, 3C, and medical fields.

13 years of ingenuity, focusing on global industrial-grade solid-state laser manufacturing. RFH covers the range of lasers from green to deep ultraviolet. Its products have been used in the field of precision processing due to its fast speed, high precision, high stability, and small and exquisite characteristics. Establish an excellent brand image.

Break through, explore, try, and change. In 2020, RFH's new generation S9 ultraviolet laser will be launched on the market!

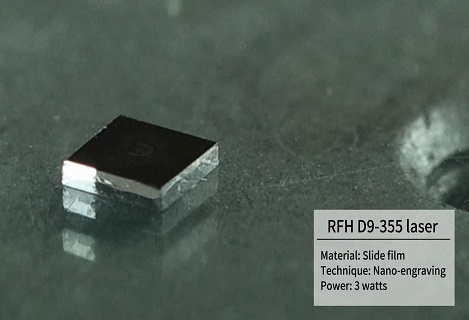

According to market development needs, RFH's newly launched S9 series pulsed ultraviolet solid-state lasers in 2020 are smaller in size, more exquisite in design, and more stable in light output than similar products. The small and exquisite design means that users do not need to make a large optical path, which can greatly reduce costs, save space, and have good mobility. It is easy to install in the field of equipment such as flying marking. The S9 ultraviolet laser is not only compact, but also has a more stable cavity structure and stronger scalability than similar products. The same cavity can produce lasers of different powers, and the stability of different power ranges is greatly improved

At the same time, superior product quality is more competitive.

Ultraviolet lasers usually output wavelengths below 0.4μm, which is the main advantage of processing polymer materials. Unlike infrared processing, ultraviolet micro-processing is not essentially a heat treatment, and most materials absorb ultraviolet light more easily than infrared light. The short wavelength of ultraviolet itself has advantages for the mechanical micro-processing of metals and polymers. It can be focused to a point on the order of sub-micrometers, so it is widely used in the processing of small parts.

For machine manufacturers, a good solid-state laser can effectively improve production efficiency and provide terminal equipment with stronger market competitiveness. The new product series of RFH pulsed ultraviolet solid-state laser S9 has a laser wavelength of 354.7nm and a wide range of repetition frequency (single pulse to 200kHz), which can be absorbed by the material and is less destructive to the material. And it has superior beam quality (M2<1.2), which is strictly guaranteed in all frequency ranges; pulse width is <20ns@30k, and the heat-affected area is small during processing.

S9 series UV lasers also have unique Q-switching control technology, full digital intelligent power control, simple operation, low cost of hands-on, and suitable for various laser application control needs; the internal cavity self-purification system makes the laser long life, stable operation, and low Maintenance costs. We fully consider the convenience of machine control in the workshop, so the laser also supports communication with the computer, and the laser can be controlled externally through RS232.

After 13 years of development and precipitation, RFH laser currently has a senior laser research and development team composed of professors, experts, and doctors at home and abroad. It has established an application process research and development department, a laser research and development department, and an electrical research and development department. It has obtained dozens of national patents and software It is a "high-tech enterprise" and "Shenzhen high-tech enterprise". The rich technical reserve is the core competitiveness of RFH laser.

In terms of product guarantee, we will provide customers with a full set of services including procurement-quality inspection control before production-rigorous assembly process-finished product testing-warehousing quality inspection-pre-delivery inspection-after-sales service to overcome your purchase, installation, commissioning, and use All aspects of technical problems, and provide high-quality after-sales service, layer by layer to ensure stable quality and the consistency of equipment parameters and actual operating parameters.

At present, RFH Laser has launched the 3W-5W S9 series of ultraviolet lasers, which will increase to 8W, 10W, 12W, 15W in the future. This series can be widely used in electronic product marking, electrical appliance shell marking, food and drug production date Marking, consumer electronics micromachining, etc.