RFH's customer buy 15w and 20w UV tube cutting PCB Circuit Boards

Jan 11 , 2023RFH's customer buy 15w and 20w UV tube cutting PCB Circuit Boards

As a service provider for laser cutting in contract manufacturing, we have been operating successfully since 1989. We cut printed circuit boards and circuit boards from various materials efficiently, cleanly and cost-effectively.

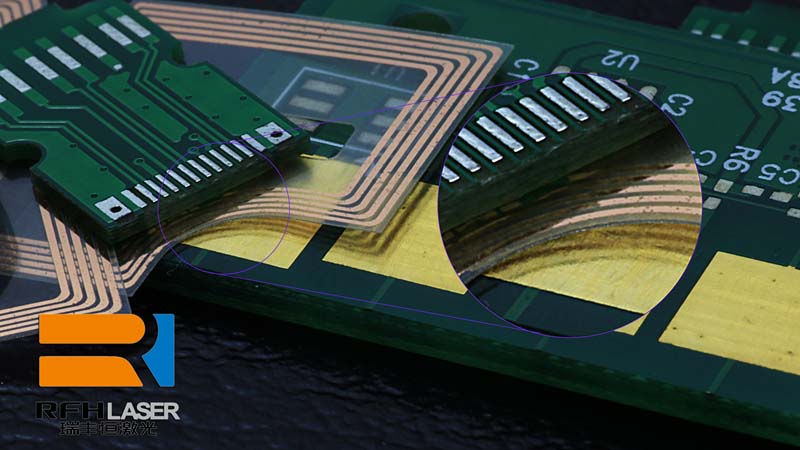

UV Laser Diode cutting PCB with reduced thermal damage

Processing of Circuit Boards With UV or USP Lasers

The ultraviolet (UV) laser or the ultrashort-pulse (USP) laser is a universal tool for processing of materials. The precisely focused laser beam produces ultrafine, clean contours in a wide variety of materials and circuit board types:

Multilayers

Flexible circuit boards

Rigid-flex boards

Thin rigid substrates

Tab-routed panels

HF materials

Composite materials

Innovative Laser Cutting Processes and Technologies

Cutting Through Multiple Layers

The focused laser beam reliably cuts through all layers in one or several passes and can be set to defined depths. It is suitable, e.g., for separating rigid and flexible circuit board components in multilayers or for cutting films made of thin and sensitive materials.

Material-Friendly, Noncontact Material Processing

The unpopulated materials to be processed are held in place by a vacuum table without the use of clamping tools. Due to the noncontact nature of the processing, there is no warpage, even in thin materials – this gives the process a clear advantage over milling or punching.

ESD-Compatible Carrier System

For circuit card assemblies (assembled circuit boards), an ESD-compatible carrier system that securely holds the individual panels in place during and after singulation is used. The parts are additionally protected against unintentional damage. All carriers are designed by our specialists and manufactured in-house.

No Burring

The UV/USP laser used vaporizes the material that is struck, so no burr forms. The minimal heat-affected zone prevents delamination of the material composites.

CleanCut Process

For meeting especially high demands, the so-called CleanCut process is used with a USP laser. This process guarantees the highest edge quality without smoke residues or particle buildup.

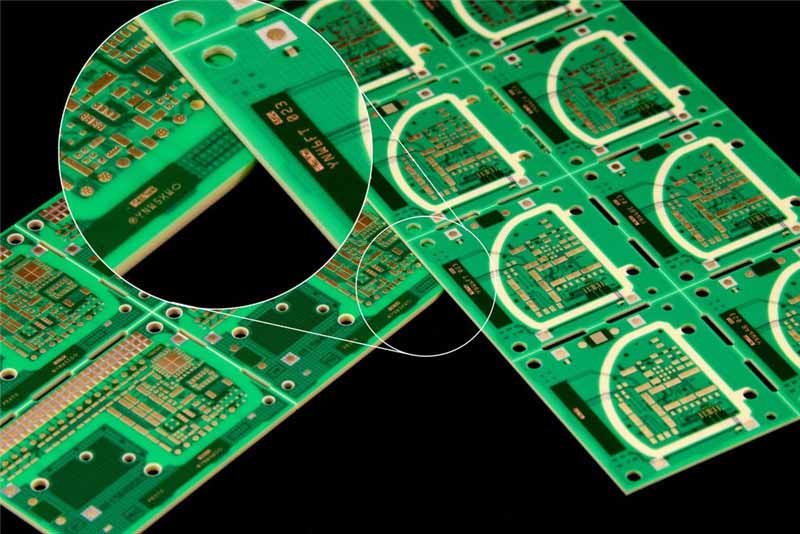

The results of laser cutting are precise, nearly radius-free contours. The cut edges are smooth, vertical, and clean – even with the most complex of geometries. The process ensures maximum dimensional stability, edge quality, and throughput.

Advantages of 15w and 20w UV tube Laser Cutting

Clean cut edges without burr or dust formation

Cutting of extremely fine contours and practically radius-free inner edges

Minimal thermal effects, i.e., no delamination

Laser cutting of various material thicknesses and combinations in a single operation

Singulation of assembled circuit boards

No clamping device or protective cover necessary

Maximum board utilization because no space has to be kept free for cutting channels