RFH High Power UV Laser Revolutionizes PCB Cutting

In the fast-paced world of technology, where innovation is key and precision is paramount, RFH brand high power UV lasers have emerged as a groundbreaking solution for cutting printed circuit boards (PCBs). With their exceptional performance, these lasers have revolutionized the PCB manufacturing industry, pushing the boundaries and setting new standards in accuracy and efficiency.

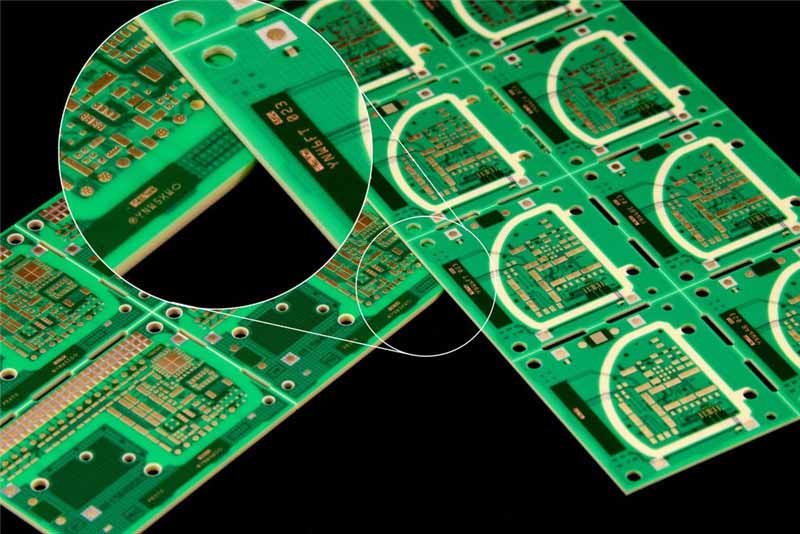

Gone are the days when traditional cutting methods were the norm. RFH high power UV lasers have paved the way for a new era of PCB cutting, delivering unparalleled results that inspire awe and admiration. The UV wavelength used in these lasers enables precise and clean cuts, allowing for intricate designs and intricate pattern formations. It's as if the laser possesses a magical touch, effortlessly transforming ordinary PCBs into works of art.

The secret lies in the advanced technology and meticulous engineering behind RFH high power UV lasers. These lasers harness the power of photons, converting them into a focused beam of sheer intensity. With this concentrated energy, they effortlessly slice through the PCB material with surgical precision. Every cut is flawlessly executed, leaving behind smooth edges and crisp lines, showcasing the laser's prowess in the realm of precision cutting.

Not only does RFH's high power UV laser excel in precision, but it also boasts impressive speed and efficiency. Time-consuming and laborious processes are a thing of the past, as these lasers can effortlessly handle high-volume cutting with ease. With every pulse, the laser swiftly glides through the PCB, ensuring that production timelines are met without compromising on quality.

The advantages of RFH high power UV lasers extend beyond their cutting capabilities. These lasers are designed with durability and longevity in mind, ensuring that they can withstand the demands of continuous operation. Their robust construction guarantees reliability, minimizing downtime and maximizing productivity. Additionally, they are equipped with advanced cooling systems, preventing overheating and maintaining optimal performance even in demanding environments.

RFH high power UV lasers have captured the attention of PCB manufacturers worldwide, propelling them to the forefront of the industry. Their ability to elevate the quality of cuts, enhance productivity, and withstand the rigors of manufacturing has made them an indispensable tool for those seeking the pinnacle of precision in PCB cutting.

In conclusion, RFH high power UV lasers have redefined the art of cutting PCBs. With their unrivaled precision, speed, and durability, they have become the go-to choice for manufacturers aiming to achieve flawless results. As technology continues to advance, RFH lasers stand as a testament to the limitless possibilities of laser cutting, pushing the boundaries of what is deemed possible and setting new standards in the industry.