RFH high power uv laser marking plastic, glass engraving, PCB cutting and SLA 3D printing

There are many materials in our life, and these materials require many processing methods. If multiple processing methods can be produced by the same machine, it will greatly save the production cost and reduce the redundancy of operators. Fortunately, RFH high power uv laser is such a machine that can perform different operations on multiple materials at the same time.

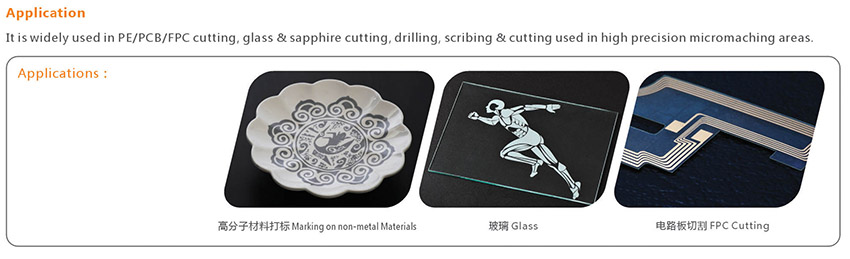

The well-known function of RFH high power uv laser is marking on plastics. In addition to this outstanding technology, RFH high power uv laser can also perform glass engraving, PCB circuit board engraving and cutting, SLA 3D printing, etc. Production. RFH high power uv laser is produced by emitting 355nm high power uv laser to scratch on the surface of the material.

The laser beam energy of RFH high power uv laser is very high, but because the thermal effect is basically zero, it will not cause any damage to the surface of the material, nor will it cause the material with a lower melting point to burn or melt.

Secondly, the RFH ultraviolet nanosecond solid-state laser has a very long running time and can stably deliver ultraviolet laser light for more than 24 hours. The temperature is stabilized and the equipment is operated through two methods of air cooling and water cooling, and the positioning system is always on standby during operation. Marking and cutting QR codes on very small plates such as PCB boards to complete high-tech products required by the market.

In addition, the precision of RFH high power uv laser is very high, reaching about 0.02mm, fully meeting the requirements of the above functions, and reaching the current physical limit.

Just imagine, if there is a high power uv laser capable of glass engraving, plastic marking, and PCB board engraving and cutting, it can be customized, stable enough and meet the high-end needs of the market while having multiple functions. Who can say that RFH high power uv laser is not the leader and sharp weapon in the laser industry?