In the Belarus area, a customer recently purchased an RFH green laser for cutting tab copper foil. The behavior of this purchase is of great significance to this customer, because it will increase its production efficiency, reduce costs, and improve product quality.

In the process of selecting a green laser, the customer conducted an in-depth investigation and comparison to ensure the performance and reliability of the selected equipment. In the end, they chose the RFH green laser because it has the characteristics of high precision, high speed and high efficiency, which can meet their production needs.

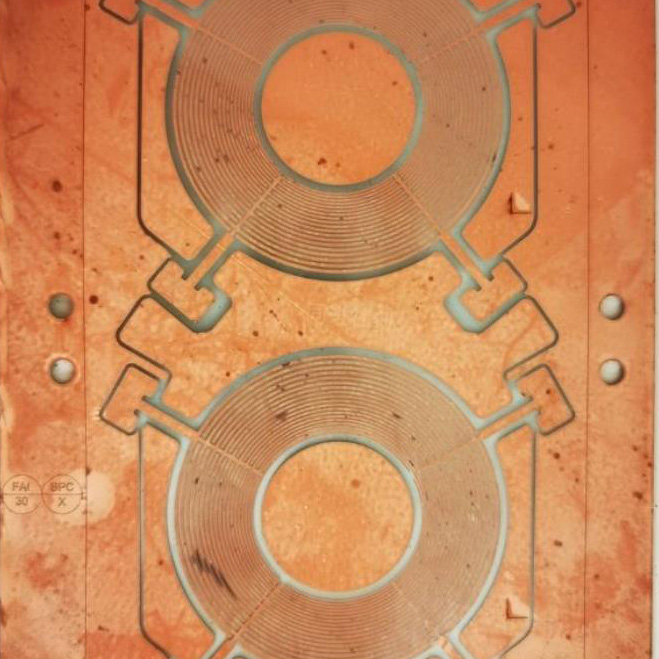

There are many advantages to using a green laser for tab copper foil cutting. First, it can improve production efficiency, because the green laser can complete the cutting job in a short time, and does not require excessive human resources. Second, the use of green lasers reduces costs because it reduces material waste and reduces maintenance costs over long periods of use. Finally, using a green laser can improve product quality as it reduces errors and can provide better results in high-precision cutting.

By purchasing RFH green lasers, Belarus' customer has achieved a greater competitive advantage in the industry. Their output has increased, their costs have decreased, and their product quality has improved significantly. At the same time, they are also satisfied with the performance and reliability of the RFH green laser. Such a purchasing decision not only helps to improve the production efficiency of the enterprise, but also improves the competitiveness of the enterprise and makes it more successful in the market.