RFH 3w5w UV nanosecond laser for SLA 3D curing printing

Ultraviolet laser is one of the important inventions in the 1960s. Its good monochromaticity, directivity, strong coherence and high power density and other characteristics make ultraviolet lasers play extremely well in many fields. Today, when 3D printing technology is very prominent, ultraviolet lasers have broadened new industries.

The RFH ultraviolet laser has a wavelength of 355nm, which is a cold light source, can be well absorbed by materials, and has low destructive power, which reduces the cost of loss. Secondly, the ultraviolet laser has a short wavelength and a large pulse width, and acts on the surface of the material for a short time, so the time of thermal effects is minimized to protect the safety of the material.

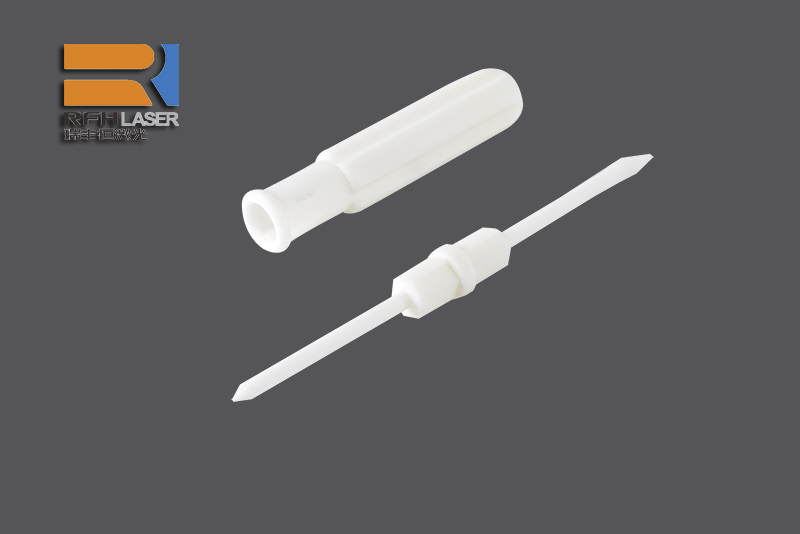

In addition, the RFH ultraviolet laser spot is small and concentrated, and the ultra-high energy beam only needs to run in an instant for printing production. In 3D printing, the RFH ultraviolet laser irradiates the liquid photosensitive resin with pulsed ultraviolet waves, and completes the final curing and molding with the help of the connected scanning galvanometer. Therefore, RFH is fully able to meet the needs of 3D printing customization, and helps enterprises to carry out mass production and individual customization in terms of precision, quality, speed and innovation.

The curing quality of the resin is affected by the scanning speed of the 3w 5w UV laser on the page, the spot size and the continuous output power of the laser. Obviously, as a leading company in the laser industry, RFH fully meets this advantage, so it has also been favored by many 3D printing companies on the domestic network. It has shown amazing advantages in this field and achieved great success.