RFH 355nm UV laser used in 3M mask marking

The 3M mask marking process has been upgraded from the original inkjet marking to ultraviolet laser marking, with fast speed, high precision and high stability

3M mask UV laser marking, fast, high precision and high stability

RFH 355nm ultraviolet laser is widely used in 3M masks to mark date information, with fast speed, high precision and high stability, and it plays an important role in identifying authenticity of signs.

As the new crown pneumonia epidemic continues to escalate globally, the global demand for protective equipment has increased significantly, especially for personal protective equipment such as masks. As a world-renowned mask manufacturer, 3M has also become a hot commodity with the spread of the new coronavirus.

3M is currently increasing the production of masks on a large scale globally. In addition to 3M's factories in China, including factories in other Asian countries, factories in Europe and the United States are also increasing production capacity. Among them, the Chinese factory has been activated for 7 days before the Spring Festival. 24-hour full-capacity production to ensure the supply of masks. In addition, 3M has also tried every means to make improvements in all production links to speed up production. Among them, the marking has been upgraded from the original inkjet marking to the ultraviolet laser marking.

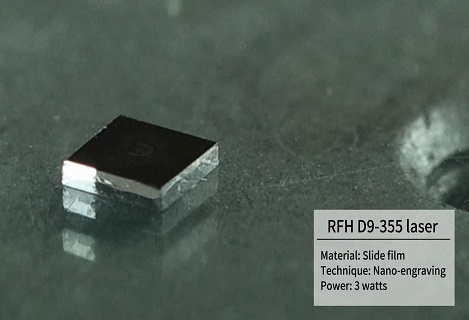

Ultraviolet laser marking uses the laser thermal effect to ablate the surface material of the object, thereby leaving a permanent mark. It has the advantages of non-contact marking, low cost, no consumables, good permanence, no deformation, no pollution, high speed, high stability, and high precision engraving.

RFH ultraviolet laser has three remarkable characteristics: fast speed, high precision, and high stability. This type of laser etching technology can play an important role in identifying the authenticity of signs.

The spot ellipticity of the RFH 355nm ultraviolet laser is >90%, the pulse width is <20ns@30k, the heat affected area is small, and the beam quality M2<1.2 is strictly guaranteed in all frequency ranges. Therefore, when marking the production date of the 3M mask, it is not The material will be scorched, and the yield rate is guaranteed.

In addition, the core components of its pump and Q switch are imported brands, and the parts cooperate with domestic first-line brand suppliers. From the source of the material procurement ecological chain, ensure the quality of each component. Moreover, the assembly process (the whole dust-free workshop), finished product testing, warehousing quality inspection, and pre-shipment inspection all have a rigorous quality management system mechanism, which is checked at all levels.

Therefore, comparing the materials and parameters, the RFH UV laser marking is obviously more stable.

Of course, its value does not stop there.

The Expert Ⅱ 355nm UV laser also has a fully digital intelligent power control technology independently developed by the RFH PhD R&D team, which can update the power control system function modules in time, and improve the function modules according to laser requirements; it has an internal cavity self-purification system to make the laser Long life, stable operation; integrated design, convenient equipment integration; with unique Q-switching control technology, suitable for various laser application control needs, with it, it is so easy to expand the laser marking business.

RFH 13 years of hard work, not only satisfied with the manufacture of high-quality lasers, we also consider from the user's point of view, launch a complete system sales program of power supply + laser + cooling system, to ensure the stability of the entire laser system, to give full play to the best performance. Because of this, we have won high recognition and good reputation from users in all walks of life at home and abroad, and established an excellent brand image in the nanosecond laser industry.