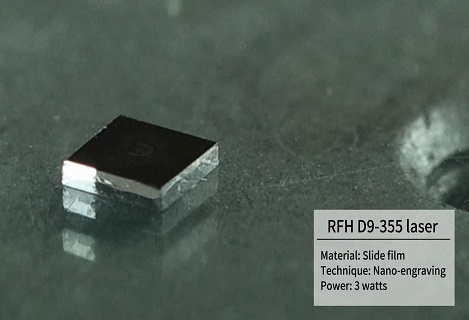

RFH 15W High Power Nanosecond UV Laser for Stripping Paint on Glass

The RFH 15w UV laser has been used in the paint stripping process on glass for more than ten years. It not only plays a very important role in the development of glass paint stripping process, but also makes many glass companies benefit a lot from it.

Cary from Malaysia recently came to RFH and wanted to order a 15w UV laser Expert III 355 series through RFH for glass stripping.

RFH gave Cary a detailed introduction to the operating principle of the RFH UV laser. The non-contact processing method surprised Cary, who has always used the traditional paint stripping method, and was very satisfied with its processing accuracy of 0.02mm.

Secondly, the RFH ultraviolet laser can not only strip the paint on the hard glass surface through the laser beam, but also perform a series of productions such as marking, cutting, and drilling, which surpasses the same type of products in terms of multi-purpose.

The RFH high-power ultraviolet laser is also equipped with a unique Q-switching technology, which is connected to other machines through software, which facilitates the manufacturer's production, and is dust-free and pollution-free. The production method without adding other materials meets the increasingly stringent environmental protection requirements. Requirements, to avoid the damage caused by random splashing of glass fragments.

RFH UV lasers helped Cary replace the brand-new glass stripping paint technology, making glass stripping paint production faster and more convenient, and improving quality while reducing costs. RFH grows and progresses with all enterprises.

Expert III 355 series ultraviolet semiconductor pump pulsed solid-state laser adopts unique laser cavity design, acousto-optic Q-switching technology, and high-precision cooling system, small size and high integration. It has short pulse width (<20ns@40k), superior beam quality (M²<1.2) and perfect spot characteristics (spot ellipticity>90%). Widely used in PE/PCB/FPC cutting, glass, sapphire cutting, and high-precision micromachining for drilling, scribing, cutting and other fields.

1. The laser wavelength is 354.7nm, and the repetition rate covers a wide range (single pulse to 200kHz)

2. Excellent beam quality (M2<1.2), strictly guaranteed in all frequency ranges; pulse width<20ns@40k, small heat-affected area during processing

3. The unique Q-switching control technology is suitable for various laser application control requirements; the inner cavity self-purification system makes the laser have a long life and stable operation.

4. Full digital intelligent power control technology, simple operation and convenient monitoring

5. Support communication with computer, external control of laser via RS232

6. Integrated design, convenient for equipment integration