Nanosecond 355nm UV laser soucre for FPC flexible circuit board cutting

Feb 10 , 2023Nanosecond 355nm UV laser soucre for FPC flexible circuit board cutting

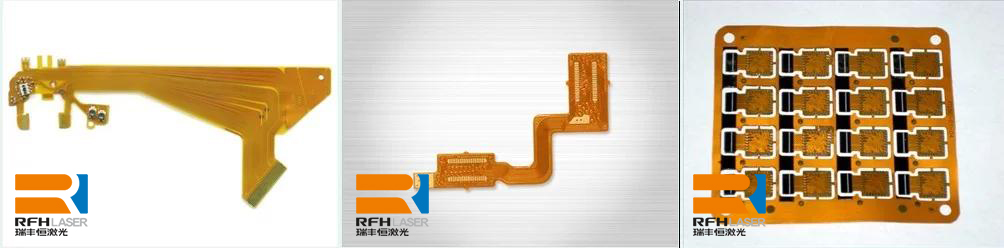

FPC, which is what we usually call a flexible circuit board, has the characteristics of high wiring density, light weight, thin thickness, and good bendability. Many laser technologies are used in the production of FPC, such as laser precision marking, laser etching, laser hollowing, laser cutting, etc. Today, Ruifengheng will briefly introduce laser cutting as an example. (Other laser processes have also been introduced in previous press releases)

At present, the laser used in the FPC laser cutting process is a 355nm ultraviolet laser with a power of 8W to 10W. The reason is the same as other circuit board cutting and processing. The 355nm UV laser is used because of its beam quality. The UV laser is a "cold light source", and its laser cutting heat-affected zone is very small. The FPC laser cutting machine of ultraviolet solid-state laser has a cutting heat-affected zone as small as 10 μm, which is very conducive to improving production efficiency. The reasons are as follows:

1. As we all know, laser cutting uses high-energy laser beams to burn materials, so as to achieve the purpose of cutting materials. Therefore, the smaller the cutting heat-affected zone, the less the burned area, so that the FPC material can be used to a greater extent, resulting in greater production benefits;

2. The smaller the cutting heat-affected zone, the smaller the impact on the finished product, and even save the subsequent reprocessing, thereby improving the processing yield and improving production efficiency.

3. RFH Nanosecond 355nm UV laser soucre is an integrated design, no need to worry about how to match the power supply and other accessories, it can be applied directly, and it can be applied to the processing of various materials, one machine with multiple functions saves the high cost of new product line construction;

Because our UV laser can maintain consistent stable and durable quality, it has won the high recognition of thousands of users. When purchasing a laser cutting machine, many processing manufacturers will pay attention to whether the laser used is produced by Ruifengheng. Such a good reputation is not easy for RFH

RFH has been deeply involved in the research and development and production of laser technology, from procurement, pre-production quality inspection and control, to rigorous assembly process, finished product testing, warehousing quality inspection, and then to pre-delivery inspection, after-sales service, continuous improvement, Continuously supply users with more stable, efficient and integrated high-end industrial-grade lasers. We have persisted in this way for 16 years. In the future, we will continue to persevere.