Many laser optics applications are shifting towards using shorter UV wavelengths because it allows for improved resolution and very small and precise feature generation with minimal heating to surrounding areas. Until recently, the high cost and bulky size of continuous wave (CW) UV laser sources have traditionally prevented them from being used in many situations, especially in university research. Now, a new wave of compact, cost-effective UV lasers has broken down this barrier, resulting in an expansion of UV applications ranging from micromachining, to UV Raman spectroscopy, to disinfection for the inactivation of pathogens.

Why Use UV Lasers?

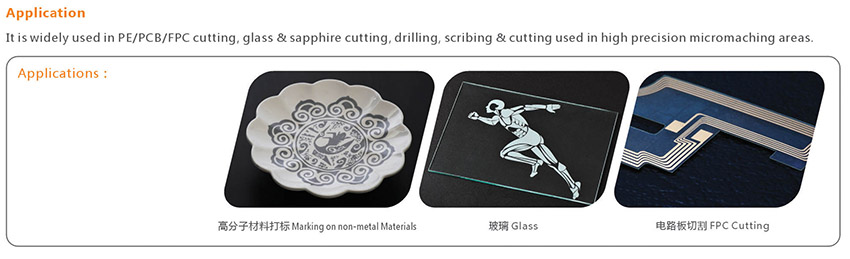

UV lasers can achieve higher spatial resolutions than infrared or visible lasers because focused laser spot size is proportional to wavelength. This allows them to be used in precise defect inspection in the semiconductor industry or in micromachining. When processing many materials, UV lasers can directly break atomic bonds rather than vaporizing or melting material, resulting in reduced peripheral heating. The high energies of UV wavelengths are ideal for exciting fluorescence in biomolecules including proteins, which is useful in a wide range of biomedical applications. Additionally, UV lasers can be used in highly-effective disinfection systems because they can sanitize surfaces by delivering high-power UVC radiation (wavelengths between 200 - 280 nm) more efficiently than UVC lamps or LEDs.1

disinfecting surfaces to eliminate potential pathogens

UV lasers are highly beneficial in a wide range of applications including fluorescence microscopy biomedical systems

Figure 1: UV lasers are highly beneficial in a wide range of applications including fluorescence microscopy biomedical systems (left) and disinfecting surfaces to eliminate potential pathogens (right).1

What Is Wrong with Older UV Laser Technologies?

Continuous-wave (CW) UV lasers have traditionally functioned by using ionized argon gas as the gain medium or frequency quadrupling near-infrared neodymium lasers. Frequency quadrupled systems require two external resonant cavities to double the frequency of the initial beam once, then repeat this process in an additional cavity.2 These systems are complex and both them and argon ion lasers are at least as large as two shoeboxes, which prevents them from being used in portable devices.

The New Generation of Accessible UV Lasers

Advances in UV laser technology have resulted in smaller, less expensive devices. New, praseodymium-doped yttrium lithium fluoride (YLF) lasers developed by RFH Laser produce a 261nm laser beam through frequency doubling rather than frequency quadrupling .2 This greatly reduces system complexity and the number of components required. These lasers operate similarly to laser diodes and do not require complicated electronics for locking resonance cavities or stabilizing temperatures.