Low thermal influence, RFH solid-state UV laser becomes the first choice for screen cutting

Wire mesh is also known as tulle, gauze, and screen. It includes natural wire mesh, synthetic wire mesh, metal wire mesh and other types. Silk mesh is usually soft and difficult to cut.

RFH UV laser s9 formally stepped into the field of screen cutting a long time ago. The wire mesh is very soft, and its internal fiber composition is relatively dense. In the past, the wire mesh cutting consumes more materials such as blades, and because it is easy to bend during the cutting process, the cutting accuracy is low.

RFH ultraviolet laser adopts spot projection method in the cutting process, as long as the screen is straightened, the cutting position can be accurately positioned, and the cut is neat, with an accuracy of about 0.02mm.

Secondly, although the RFH ultraviolet laser cuts by emitting energy beams, its thermal effect is zero during operation, so whether it is a natural wire mesh or an artificial wire mesh, it will not be burned or damaged during the cutting process, ensuring The stability of the processing cost.

RFH UV lasers have continuously entered many fields over the years, and in the process of helping and participating in the screen cutting process, the screen production line has been pushed to a new level of efficiency, benefiting more manufacturers.

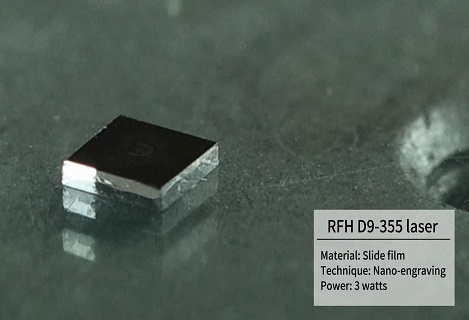

RFH s9 uses a 3w-10W ultraviolet laser, which has a fast processing speed and is more handy when cutting PCB and other materials.

The laser wavelength of RFH s9 is 354.7nm, the repetition frequency covers a wide range (10kHz to 200kHz), and has excellent beam quality (M2<1.2), and it is strictly guaranteed in all frequency ranges.

The most powerful part of RFH is the power control system, which has the technical force of self-developed power control module. Through the unique Q-switching control technology, it is suitable for various laser application control requirements. The laser has a long life and stable operation.

Finally, it is the intelligent manufacturing that complies with the industry 4.0 standard. RFH adopts all-digital intelligent power control technology, which is easy to operate and convenient to monitor. In terms of operation, RFH supports communication with the computer, and the laser can be controlled externally through RS232 to easily realize remote control.