Laser etching and engraving glass way

Dec 22 , 2022Laser etching and engraving are great ways to personalize and create designs on all kinds of glass.

With the advancements in laser engraving technology, such as the rotary axis, it's even possible to work on curved glass surfaces such as bottles and drinking glasses.

The non-contact nature of laser engraving offers several advantages over traditional glass engraving techniques like sandblasting and CNC engraving.

However, the reflective nature of glass can present various challenges that you need to be vary of.

This article discusses the process of laser engraving and etching glass, its applications, and the types of glass used while comparing it with other techniques used for engraving glass.

In the end, I'll also recommend some laser cutting machines and services that offer etching or engraving of glass.

Laser Etching and Engraving Glass- The Basics

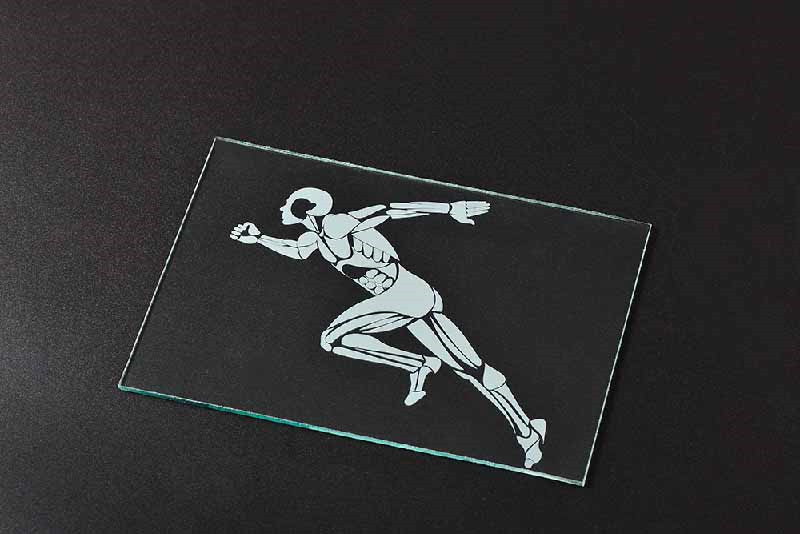

Laser etching and engraving glass produces a permanent mark with a frosted look. Laser etching glass alters the surface at a maximum depth of 0.001” and requires comparatively lower laser power than engraving. Generally, UV laser is ideal for engraving/etching glass.

Glasses can be etched, engraved, scored, or cut using a laser. This article strictly talks about the laser etching and engraving aspects of glass.

Laser etching and engraving are two of the most popular methods used in personalizing glassware.

Etching Glass

Mirror engraving done on COMGO Z1

Laser etching the glass of a mirror

When glass is etched, the laser alters the topmost surface layer of glass. Typically, the maximum depth-of-cut in etching is around 0.001".

Masking and polishing the glass, and reducing the grayscale of the image by 20% will improve the quality of etching and produce a high-contrast mark.

Furthermore, using low-resolution images will result in better etching on glass because higher resolutions can produce deep, crowded fractures, thereby affecting the clarity of the mark.

Engraving glass

Engraving and cutting glass using xTool D1 Pro

Engraving in glass by using a laser to create micro fractures

Laser engraving vaporizes the material and produces a cavity on the surface of the glass.

Generally, laser engravings on glass have a maximum depth of around 0.02" to 0.125".

Sub-Surface Laser Engraving (SSLE) is a popular technique used to engrave 2D and 3D images inside a block of glass.

In this technique, an additional parameter called Z-factor or height is considered to focus the laser beam inside a glass.

Glass having high optical clarity are used for producing SSLE. This helps the laser beams to effectively pass through the glass and focus on the right spots.

Although laser etching or engraving glass can throw up some challenges, there are various techniques you can learn to improve the quality of your engraving.