High-power UV nanosecond solid-state laser drills copper substrates without deformation or bursting

Sep 03 , 2022High-power UV nanosecond solid-state laser drills copper substrates without deformation or bursting

Industrial Revolution Rising Star! 20W high power UV laser drilling copper substrate

RFH New Generation Ultraviolet Solid State Laser High Power and High Frequency Processing Copper Substrates

In the digital age, high-power electronic components are very common. As power increases, heat dissipation requirements also increase. Metal substrates are the mainstream choice. Among them, copper substrates are the most common, and the processing difficulty has also increased.

In terms of processing difficulty, the biggest difficulty faced by copper substrates is punching. Especially when punching millimeter-level through holes, the word "broken knife" is often heard.

Since copper, a metal, is much harder than composite organic materials, when drilling, the drill bit is severely worn, and it is easy to break the knife. Of course, in addition to high hardness, "copper scraps" are also a factor that cannot be ignored. These copper scraps attached to the cutter head may also be the culprit of the broken knife.

Therefore, a lot of "anti-stick copper wire" drill bits have been produced on the market, which is also considered a painstaking effort.

No matter how difficult the processing is, the basic operation of punching copper substrates will only become more and more demanding in the future, and the requirements for punching will become more and more refined, and even small holes of 0.5mm can be easily reached. In this case, it seems that the only way is to customize the tool. In addition to customizing the drill point angle, parameters such as the helix angle should also be considered.

The problem is that no matter how customized it is, there is still no escape from the barriers of high wear, easy to break the knife, and difficult heat dissipation. In this case, we can only completely change the way of thinking and use a completely different processing method.

We don't need to waste time on the tool and switch directly to the non-contact machining solution - the laser, which may be the best solution.

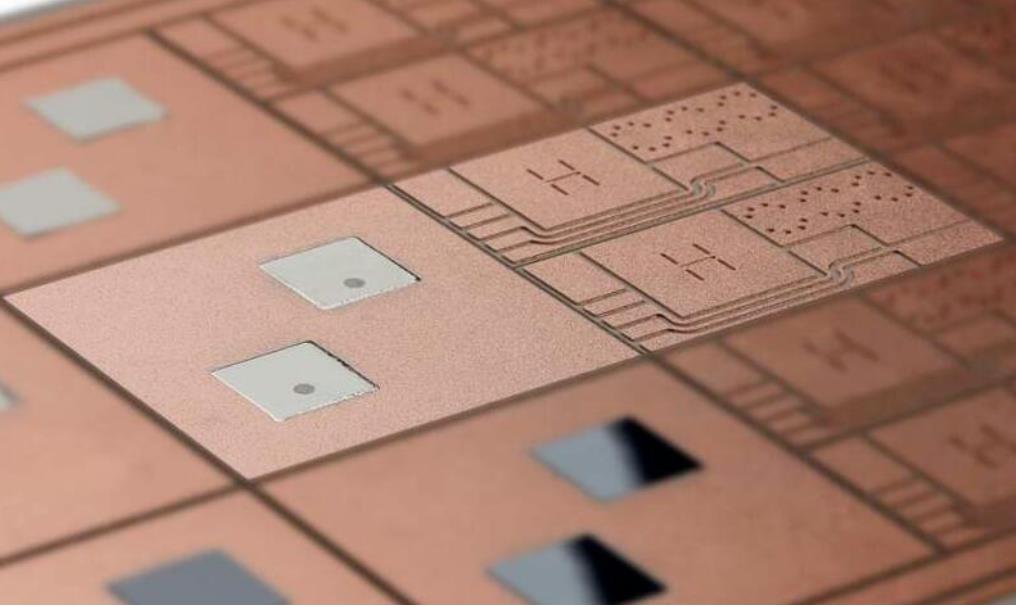

Using RFH high-power UV laser, through extremely high instantaneous power consumption, drilling is easy and efficient, and at the same time has impeccable processing accuracy. Since the laser adopts a non-contact processing method, there is no need to worry about "tool wear", "copper chips", "substrate deformation" and other issues.

Under the processing of RFH, the copper substrate is not deformed, and the efficiency and precision are extremely high. This is a new processing method in the digital age.

RFH Recommended Laser: Expert III 355 High Power UV Pulsed Solid State Laser

As RFH's next-generation UV solid-state laser, the Expert III 355 has many new features:

1. High machining accuracy:

Because RFH Expert III 355 has a short pulse width (<25ns@50k) and excellent beam quality (M²<1.2), it can easily achieve ultra-high precision of ±0.02mm, and the thermal influence range is extremely small.

2. Small size and high degree of integration

RFH Expert III 355 adopts an integrated design with a high degree of integration, which is convenient for equipment integration. In addition, due to its small size, there is no need to enlarge the optical path, which reduces the processing threshold.

3. Full digital power control

RFH Expert III 355 adopts all-digital intelligent power control technology, which is easy to operate, convenient for monitoring, supports communication with computer, and can control the laser externally through RS232, opening the door to digital processing.

4. Stable operation and long service life

The power supply is very important to the laser. RFH uses the self-developed power supply technology and adds the inner cavity self-purification system, so that the laser has a long life and stable operation. In terms of function, through the unique Q-switching control technology, it is suitable for various laser application control needs.

In digital processing,

Precision, efficiency and stability are the goals pursued by all users.

Forged by RFH laser over 15 years,

innovation,

Provide customers with new processing options.

Efforts are made to lower the processing threshold, improve the yield of finished products, and expand the territory for the enterprise.

Facing round after round of industry revolution,

RFH Laser is willing to be the leader!