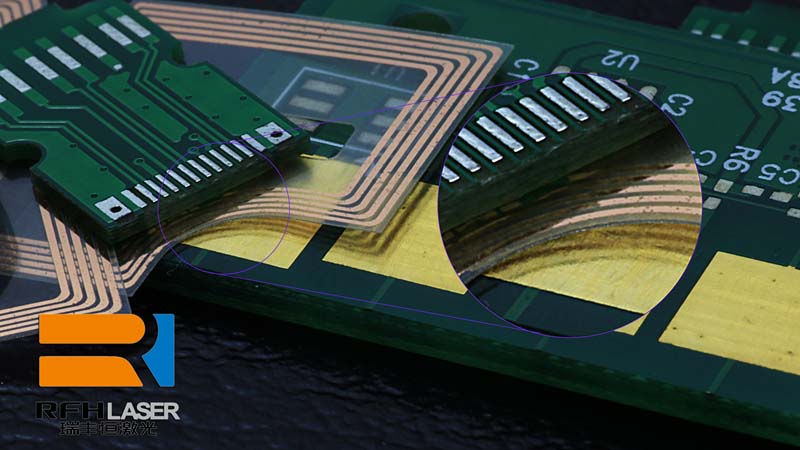

High power green laser depaneling PCB/FPC for South Korea customer

Feb 02 , 2023High power green laser depaneling PCB/FPC for South Korea customer

High power green laser depaneling or part excising can cut through metals, plastics, dielectrics, or a combination of both.

These high power green laser processes have the advantage of speed, positional accuracy, no tooling cost or wear, no part induced stresses, and no cutting oils or other contaminants.

High power green Laser scoring

High power green Laser scoring produces a limited depth ablation line in the part or material set. The depth is generally 50% of the material thickness but can be controlled to a desired depth. The scoring acts similar to the hold-tab to secure the part in the panel or sheet, but allows for individual parts to be ‘snapped’ out. Laser scoring lines can also be used as a deliberate path for stress relief or crack propagation. Prototypes utilize scoring lines in metal to accurately bend and form parts into shape without expensive forming dies.

Perforations

Similar to scoring or v-grooves, high power green laser perforations are another option for tool-less part removal from a panel or sheet. Perforations can be laser formed to any size and spacing to meet the desired removal and securement forces.

Expert III 532 series green DPSS laser, developed and produced by RFH, covers 35w in laser power with short pulse width (<25ns@50K) ,superior beam quality (M²<1.2) and perfect laser spot quality (beam circularity >90%).It is perfect for glass marking,thin film etching and surface treatment for most of the metals and non-metal materials, such as removing the oxide layer from the metal surface