Exquisite ceramic engraving and drilling can not be separated from UV laser

Website: http://www.rfhtech.com

Whatsapp(Wechat): 18928466502

Email: export06@rfhlasertech.com

Ceramics are widely used in industry. Because ceramics have a series of advantages such as high temperature resistance, corrosion resistance, wear resistance, erosion resistance, etc., they can replace many metal materials and are sufficient to cope with harsh industrial standards.

If it is distinguished according to its characteristics, taking advantage of the high hardness and wear resistance of ceramics, it can be widely used in the production of various key mechanical parts, especially in automobiles and aircraft engines (such as piston crowns).

From another point of view, ceramics also have corrosion-resistant properties, because ceramics can maintain good stability when in contact with biological enzymes, so we will also use them in biological materials (such as artificial teeth, knee joints, etc.).

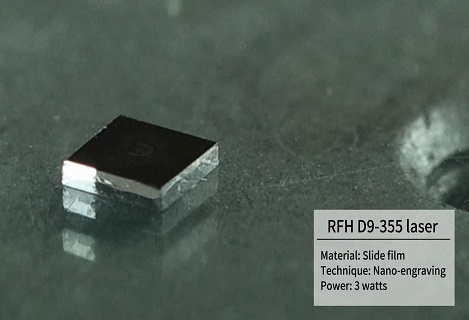

RFH high-power UV laser 5s completes 0.5mm ceramic sheet drilling

Even in the structure of nuclear reactors, many ceramic materials can be seen, but these ceramics will be specially selected and processed to make them have the characteristics of neutron absorption.

The above uses are only examples that have been widely used now. With the continuous in-depth research on ceramics, especially after the gradual maturity of nanotechnology, the combination of the two technologies has continuously improved the characteristics of ceramics, and many "composite ceramics" have been launched. .

Having said so many advantages of ceramics, in fact, processing ceramics has always been a huge challenge for modern industry, because ceramics also have some inevitable processing disadvantages, of which lack of toughness is the biggest problem.

When drilling ceramics and other processing, experienced workers will reduce the speed of the electric hammer when drilling the surface, and then accelerate when the hole is drilled. At the same time, it is necessary to spray water continuously during the drilling process, because the temperature is rapid Ascent can also cause cracking.

RFH nanosecond UV laser drills ceramics to avoid popping

In addition, I just mentioned that ceramics have the characteristics of high hardness and wear resistance, so when drilling holes in ceramics, it is necessary to select a good drill bit, and the wear of the drill bit is not small.

In addition to these processing disadvantages, modern industry has higher and higher requirements for the processing of small ceramic materials, so traditional processing methods are gradually being phased out and replaced by lasers.

Using the characteristics of laser, it belongs to non-contact processing when drilling ceramics, the edges are regular without burrs, and the efficiency is very high.

Using the RFH high-power laser, a 0.5mm ceramic wafer can be drilled in less than 5s.

RFH Recommended: Expert III 355 High Power UV Pulsed Solid State Laser

The power range of the RFH Expert III 355 UV laser is between 10W and 15W, and it has the characteristics of small size and high integration.

In addition, the RFH Expert III 355 UV laser uses a unique cavity design with acousto-optic Q-switching technology and a high-precision cooling system.

In addition, a self-purification system is added to the internal cavity, which can improve the service life of the laser and ensure stable operation for a long time.

Due to the excellent internal design of the RFH Expert III 355 UV laser, it has superior beam quality (M2<1.2), which is strictly guaranteed in all frequency ranges, pulse width <25ns@50k, and small heat affected area during processing.

RFH Expert III 355 UV laser, can guarantee ±0.02mm high precision machining

Based on such a high-quality laser beam, RFH uses all-digital intelligent power control technology, which can use the RS232 interface to externally control the laser, and communicate with the computer to facilitate operation and monitoring.

No matter how small ceramic parts are processed, the use of RFH Expert III 355 UV laser can guarantee high precision machining of ±0.02mm.

In the face of modern industry, laser is obviously indispensable. RFH has been focusing on laser for more than 15 years. Through the technical advantages of independent research and development of power supply, it has continuously tapped the potential of laser, and continuously brought laser products with high stability and high cost performance to everyone.

uv laser | green laser | Ultraviolet lasers | uv dpss laser | nanosecond laser | UV laser source | Solid State Lasers