In today's world, barcodes are everywhere, from grocery stores to online shopping websites. These small, seemingly insignificant patterns of lines can carry vast amounts of information and serve a variety of purposes. But have you ever wondered how these barcodes are engraved onto metal surfaces, where traditional printing techniques are not possible? This is where laser technology comes to the rescue, and a recent Australian customer purchase of a high-power green laser for barcode engraving is a perfect example.

The customer in question is a manufacturer of industrial machinery parts and needed a solution to engrave barcodes on metal components. Traditional printing techniques such as inkjet or thermal transfer were not applicable, as they would quickly wear off due to the harsh industrial environment. The customer researched various options and decided that a high-power green laser would be the best solution for their needs.

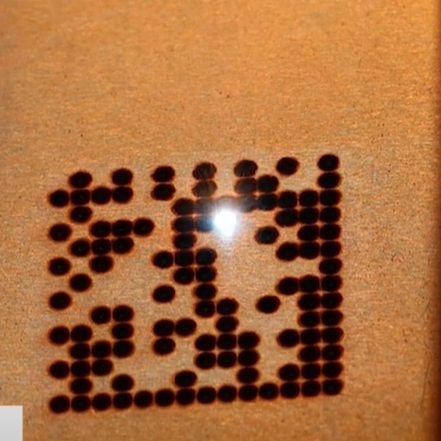

The green laser the customer purchased has a wavelength of 532nm and a power output of 35watts. It is capable of engraving barcodes on a variety of metals, including steel, aluminum, and titanium, with incredible precision and accuracy. The laser beam is focused to a point of around 50 microns, which is about half the width of the human hair. This allows for the creation of very fine lines and high-density patterns, making it an ideal tool for engraving barcodes.

But why a green laser, you may ask? Green lasers are known for being more efficient than other laser types, such as red or blue. This means that they require less power to achieve the same effect, making them more economical and environmentally friendly. Additionally, green laser light is more easily absorbed by metal surfaces, making it easier to etch high-quality barcodes.

The customer was delighted with the green laser's performance, which surpassed their expectations. The laser system's software allowed them to program the barcode parameters, including size, density, and orientation, easily. It also enabled them to engrave other designs and logos onto the metal components, adding a personalized touch to their products.

In conclusion, this Australian customer's purchase of a high-power green laser for barcode engraving is a testament to the power of laser technology and its versatility. The ability to engrave barcodes onto metal surfaces with such precision and accuracy opens up many possibilities in various industrial sectors where traditional printing techniques are not applicable. This technology is increasingly becoming an essential tool for manufacturers seeking to enhance product traceability, security, and tracking capabilities. As advancements in laser technology continue, we can expect even more significant developments and applications of laser engraving in the near future.