About Glass Laser Engraving & Etching

Oct 25 , 2022Glass laser engraving and etching have become popular techniques for producing images, patterns, and logos. Learn the basics of both methods as we prepare you to fire up that beam.

A laser is a machine that produces a beam of light through an optical amplification process. Today, lasers have become critical components of the products we use in our daily lives, ranging from bar code scanners to DVD players.

In manufacturing, lasers are used for drilling, cutting, and engraving a wide range of materials. In glass manufacturing, for example, laser engraving and etching provide several possibilities for personalization without changing the characteristics of the glass.

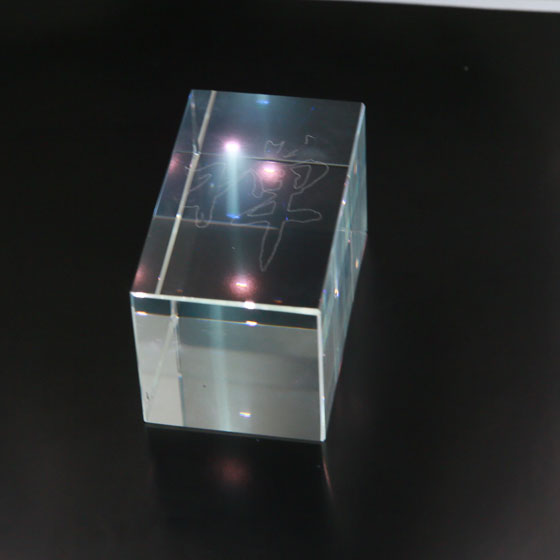

Laser engraving cuts out a portion of the material, leaving a cavity that reveals a design, with the engraved part being noticeable both through sight and touch. Laser engraving is performed with a high-heat laser that vaporizes the material. Engraving depths typically vary between 0.02″ and 0.125″ in harder materials.

Laser etching, on the other hand, does not cut into the material, but instead removes only the top layer using a less powerful machine. The depth of the “cut” is usually no more than 0.001″.

In fact, etching is a subset of engraving and is considered a chemical process, while engraving is regarded as a physical process. Both techniques have become popular for adding images, logos, and numbers on glass.

In the following, we’ll take a deeper look at both, including how they work, their benefits, and how they’re executed.

How Does Glass Engraving Work?

In a nutshell, the high-temperature laser beam vaporizes the material and cuts into it physically, leaving a cavity. With glass, this works because of its inner composition.

Glass is made by heating silicon, which melts at high temperatures and turns into a thick fluid. The molten material is then manipulated in various ways, causing it to trap air and moisture.

Whenever a laser beam hits the glass, the air and moisture between elements of silica and metal react, not the other glass elements like silicon. Specifically, they expand, and since the glass is rigid, this causes microscopic fractures at the surface of the material. It is the resulting fracturing and chipping that we see and feel as engraving.

Engraving Curved Glass

Lasers are generally easier to use on a flat surface, where there is a given focal length and distance between the lens and the surface of the material.

Engraving a curved surface (like bottles, vases, and steins) can pose a challenge, but there are workarounds allowing for some flexibility. For example, using a rotary attachment is an option. Plugged into a laser machine, it allows the glass object to rotate as the laser does its magic. Naturally, complex angles and variations in curvature can still cause problems.

Neatness and Cleaning

Although engraving glass comes down to fracturing and chipping the material, the goal is to, as much as possible, produce a shard-free pattern. To do this, most engravers place wet paper towel or newspaper over the glass.

Cleaning is always be required after engraving. For this, one can use rubbing alcohol and a paper towel or a nail brush if there are shards. Other processing options involve the use of application tape.

UV laser marking glass without burst,see what is uv laser:

How Does Etching Work?

Laser Engraving Photo on Glass

Laser etching is a subset of engraving and works the same way, except that the depth of the cut is usually no more than 0.001″. This does little more than alter the appearance of the surface, affecting properties like reflexivity. Laser etching is sometimes considered the sweet spot between laser marking and laser engraving, ideal for thin materials or jewelry.

Technically, a laser engraving machine is also a laser etching machine with the only difference being the intensity of the laser beam.

Laser engraving and etching are performed at different frequencies (wavelengths of light produced by the laser), which affect how the laser interacts with different materials. When etching is done right, it leaves the glass with a beautiful, sophisticated look because, as the laser strikes the glass, it does not destroy the material, but it leaves a frosted appearance.