3W5W laser for engraving LOGO pattern on glass has little thermal effect

Carrying out UV laser engraving on the water cup is an artistic pursuit as well as an enjoyment of life.

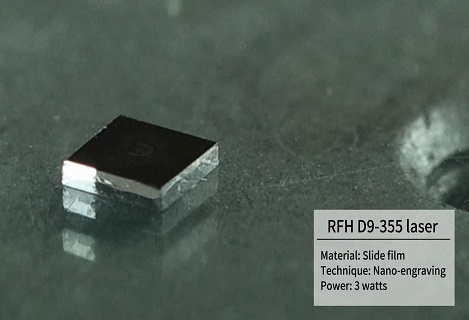

The UV marking process is realized by using the photochemical reaction between UV light and the material to cause the color to change. Using appropriate parameters can avoid the obvious removal effect on the surface of the material, and thus can mark graphics and characters without obvious touch.

Manager Li, a handicraft manufacturer from Shaanxi. The main products are glass cups, which are mostly exported to Europe, America and the Middle East. The 3W5W laser that we call for consultation this time is mainly used to replace the old laser. The old laser is also from RFH. This time I recommended the new S9 nanosecond ultraviolet laser to Manager Li.

RFH Laser has devoted 13 years of research and development, and continues to provide the market with lasers which has stable power, high integration, excellent beam quality, long life, fast speed and high precision.

The cost-effective S9 series of solid-state UV lasers developed through continuous innovation have achieved a high accuracy of ±0.01mm, while being smaller and more stable, and can be efficiently used in various fields of flight marking equipment .