355nm UV laser has fast marking processing speed for plastic switch panels

Since the popularization and application of ultraviolet laser technology on plastic switch panels, marking LOGO and "light on", "light off", "exhaust fan", "bedside lamp" and other signs have made the switch panel no longer monotonous, and UV marking is not easy to be erased. It plays a good anti-counterfeiting effect, puts an end to counterfeit products, and eliminates potential safety hazards.

The UV laser beam has no attenuation, the beam spot is uniform and compact, fast, good in light transmission, and fine marking. The coding effect is beautiful and exquisite, low-carbon and energy-saving, long life, easy to operate, extremely suitable for assembly line marking on switch panels.

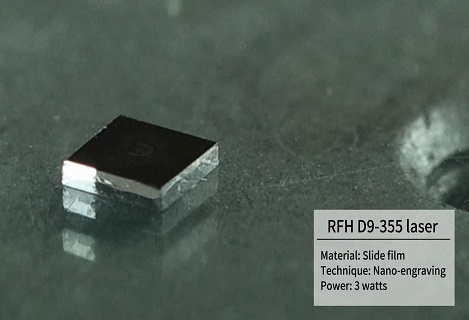

For 13 years of hard work, for the switch panel marking processing industry, the Expert III 355 series UV diode pumped pulsed solid-state laser developed and produced by RFH has a power range of 10W-15W, using a unique laser cavity design, acousto-optic Q-switching technology, and the high-precision cooling system, small size and high integration have established an excellent brand image in the field of switch panel carving.