355nm nanosecond solid-state UV laser for plastic stripping

Customers are very satisfied with the peeling effect of RFH UV laser on plastic materials

Plastic is the most commonly used material in our daily life. No matter what kind of supplies, there are more or less traces of plastic. It can be said that it is difficult for us to live without plastic. Plastic is a special material that is easily deformed at high temperatures, so in some plastic production processes, it is necessary to strip paint on the outer deformed parts.

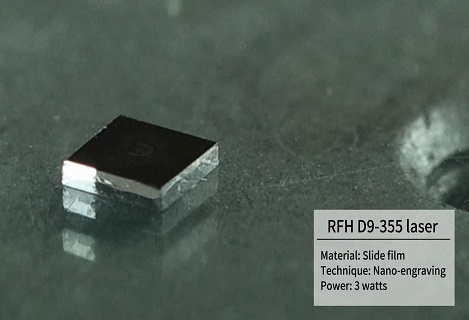

Mr. Jiang from Hubei recently came to RFH, hoping to buy RFH's UV laser for plastic stripping. What RFH recommended for him is the 355nm nanosecond solid-state UV laser S9, which is a new product of RFH. Different from ordinary UV lasers, the marking efficiency and marking properties of the S9 nanosecond solid-state UV laser are more suitable for plastic processing, and can be used to a large extent. It has the characteristics of plastic peeling paint.

The RFH nanosecond UV laser adopts semiconductor pumped laser technology combined with acousto-optic modulation technology, high-efficiency intracavity frequency conversion technology and high-precision temperature control technology, which can realize the synchronous change of temperature, frequency and wavelength light, and quickly adapt to new stripping materials. . In addition, the RFH nanosecond UV laser has a low thermal impact, which reduces the energy beam damage to the plastic surface when emitting the light spot, so that the damage is reduced, and the scrapping phenomenon during the plastic peeling process is reduced.

In addition, the RFH UV laser has high precision, and the paint stripping accuracy reaches about 0.2mm, which can fully meet the current market demand for plastic paint stripping, which makes Mr. Jiang very satisfied.

RFH's research on nanosecond UV lasers continues. In the newly opened fields, RFH will continue to work hard to lead the development of the industry and benefit more products.