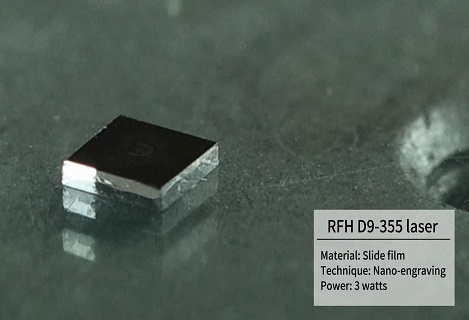

355 nanosecond solid-state UV laser for plastic stripping, light transmission

RFH Nanosecond UV Laser Marks and Strips Painted Plastics

For plastics that are heavily affected by heat, UV lasers are ideal for stripping paint

Plastics are widely used and are unreliable materials and components in all walks of life, and the demand and requirements for plastics in all walks of life are also increasing. Plastic peeling paint is painted on the plastic surface, but in fact, many painting methods will have problems such as aging, peeling and cracking, and need to be reworked. Therefore, a paint peeling method has emerged. Peel off the substrate and re-mark. So, can peeling paint and marking be combined into one?

The RFH 355 nanosecond UV laser is capable of stripping paint and re-marking in one, saving the cost of buying another machine. At present, most of the peeling methods used in the market are contact peeling, and UV laser peeling belongs to non-contact marking, which can quickly peel and mark the plastic surface, and accurately control the accuracy of the surface. Control it within 0.2mm and perform sharp processing.

The nanosecond ultraviolet laser with a repeat coverage rate of 200kHz can adapt to various plastic peeling and marking methods. The integrated design facilitates its integration with other equipment. The small size can pass the route without a huge optical path. Q technology realizes the various needs of laser applications in plastics.

In addition, the pulse width of the RFH nanosecond UV laser is precisely controlled, which can ensure that the edge of the peeling paint is free of burrs, smooth and without traces, and the RFH UV laser that operates through the all-digital intelligent power control technology supports communication with the computer. way to control and use.

The application and innovation of RFH nanosecond ultraviolet laser has been loved by many customers, and a large number of orders have also brought RFH orders one after another. The modular design concept leads the national laser industry, giving the domestic laser industry a brighter future.