15w high power UV laser cutting chip card, no carbonization and no damage

Oct 29 , 202215w high power UV laser cutting chip card, no carbonization and no damage

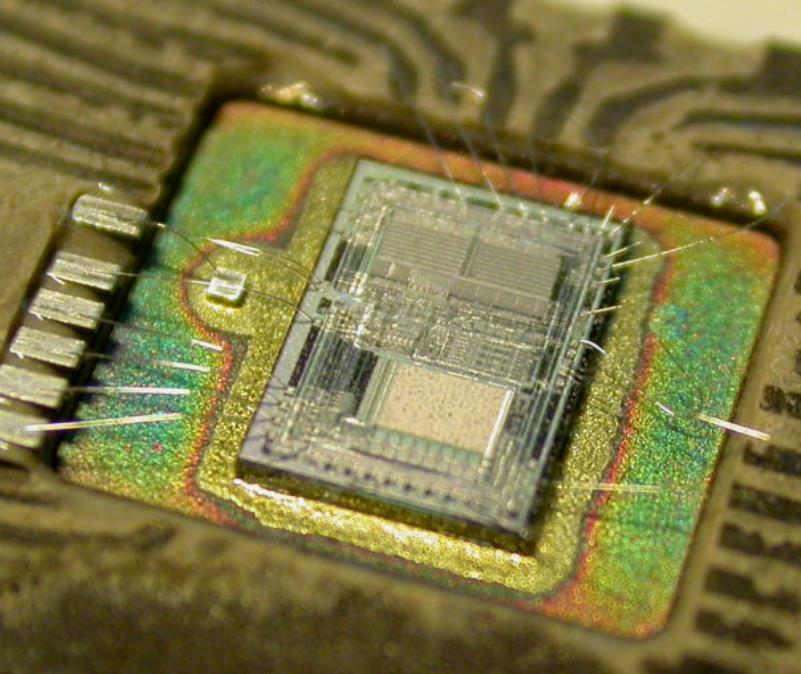

Integrated Circuit Chip (Integrated Circuit Chip) Abbreviation: IC chip. It is no exaggeration to say that IC chips in various forms are ubiquitous, ranging from car keys and access cards to aerospace equipment. As long as there is computing, it is indispensable.

According to different packaging processes, the integration of IC chips is different, and the number of diodes, transistors, resistors, capacitors, inductors and other parts is also different.

But the same is that the volume of IC chips will be compressed as much as possible, and there is a trend of getting smaller and smaller. The design integration is extremely high, and it is covered with various cables. It is extremely difficult to cut and engrave.

But for any IC chip, cutting is an indispensable link, which has also become a technical difficulty that has been difficult to overcome for many years. For a long time, traditional, physical methods were used to cut integrated circuits.

The traditional processing of IC chips is carried out by diamond saw blades (abbreviation: grinding wheel) for dicing and cutting. This method has been used for a long time, but in the face of increasingly shrinking IC chips, the limitations of physical cutting are gradually becoming more prominent.

Now any IC chip is millimeter-level, and an IC chip with a thickness of 1mm is a normal thickness. If physical cutting is used, it is easy to process defective or faulty products, which affects the final quality control.

In the face of millimeter-level IC chip cutting, non-contact laser is a good solution.

RFH uses a 20W high-power UV laser, which can accurately cut IC chips with a thickness of 1mm without mechanical stress, with less chip damage and good quality control.

Focusing on millimeter or even micron-level cutting, lasers are almost the only option, and physical cutting obviously cannot meet the ever-increasing standards.

RFH Expert III 355 High Power UV Pulsed Solid State Laser

https://www.rfhtech.com/expert-iii-355-ultra-stable-nanosecond-uv-laser-10w12w15w_p13.html

RFH has more than 15 years of research and development experience. As a high-power UV laser, the Expert III 355 has the characteristics of small size, high integration, and high precision of ±0.02mm, which can easily process precision instruments such as IC chip cutting.

In terms of design, RFH Expert III 355 adopts a unique laser cavity design and acousto-optic Q-switching technology, which can adapt to various laser application requirements.

In addition, due to the existence of a high-precision cooling system and an internal cavity purification system, the laser has a longer service life.

When RFH Expert III 355 is cutting, due to its short pulse width (<25ns@50k), superior beam quality (M²<1.2) and perfect spot characteristics (spot ellipticity>90%), the thermal impact during processing The area is small, the cutting surface is smooth and burr-free, and the precision is very high.

In terms of power control, RFH has the ability to independently develop a "laser power control system".

RFH Expert III 355 uses all-digital intelligent power control technology, which is easy to operate and convenient for later operation and maintenance. It can communicate with the computer through the RS232 serial port, which can easily realize remote control and facilitate integration with various equipment.

With such a powerful performance, the RFH Expert III 355 still maintains a small size, the integrated compact design is easy to integrate, and the user does not need to make a large optical path, which can greatly reduce the cost.

In precision machining, lasers have the unparalleled advantages of physical methods, and the advantages of precision, high efficiency, and low cost are obvious.

In the field of laser, RFH has been deeply involved for many years, has a senior team and strong technical force, and provides the best quality products and services from the perspective of users.