Latest Blog

what setting for ceramic laser marking

Oct 19 , 2023Ceramic laser marking is a process used to create permanent marks on ceramic surfaces using a laser. Ceramics are challenging materials because of their hardness and brittleness, but lasers can mark them effectively without physical contact, which minimizes the risk of damaging the ceramic. Here's a deeper dive into the application:

Lasers can induce several reactions on ceramics, depending on the ceramic type and laser parameters:

Melting or Material Removal: The laser can evaporate or remove a tiny layer of the ceramic, creating a mark.

Color Change or Discoloration: In some cases, the laser can induce a color change without removing material. This is often due to localized changes in the ceramic's structure or composition.

Video of Ceramic Laser Marking

Precision: Lasers can create very fine and intricate markings, suitable for detailed graphics, codes, and text.

Consistency: They offer consistent results from one piece to the next.

Non-contact: The non-contact nature of laser marking minimizes wear and reduces the risk of breaking or damaging the ceramic.

Permanent: The markings are typically permanent and resistant to wear, chemicals, and heat.

Identification and Traceability: For components in the electronics and medical industries, where tracking and identification are crucial.

355 Nm UV Laser Cold Light Source Marking ceramics

Decorative Engraving: In the creation or personalization of ceramic wares or jewelry.

ceramice engraving with 355nm UV laser

QR Codes & Barcodes: For product identification, traceability, and authenticity checks.

ceramics materials engrave with high power UV laser

Technical Ceramics: Many high-performance ceramics used in aerospace, automotive, and other industries require precise marking for identification and traceability.

Ceramic Tiles: Some artistic or custom tiles may be laser-engraved with patterns or designs.

High-Power 355 nm Ultraviolet Laser etching jade

For ceramic marking, specific laser types have proven to be more effective than others due to the unique characteristics of ceramics. The choice of laser type mainly depends on the desired marking effect, the particular ceramic material, and the application's requirements.

These are the most commonly used lasers for marking ceramics.

Fiber lasers emit in the infrared range, usually around 1064 nm.

They offer high peak power and good beam quality, making them effective for creating sharp, high-contrast marks on ceramics.

The markings are typically achieved through localized material removal or color change.

| arameter | Low Setting | Medium Setting | High Setting | Notes |

|---|---|---|---|---|

| Power (Watts) | 10W | 20W | 30W+ | Higher power for deeper marks. |

| Speed (mm/s) | 100 | 500 | 1000 | Slower speeds for deeper, clearer marks. |

| Frequency (kHz) | 20 | 30 | 50 | Adjust based on desired mark clarity. |

| Pulse Duration (ns) | 100 | 150 | 200 | Shorter pulses for sharp, fine details. |

| Hatch Distance (mm) | 0.01 | 0.05 | 0.1 | Affects the spacing between marking lines. |

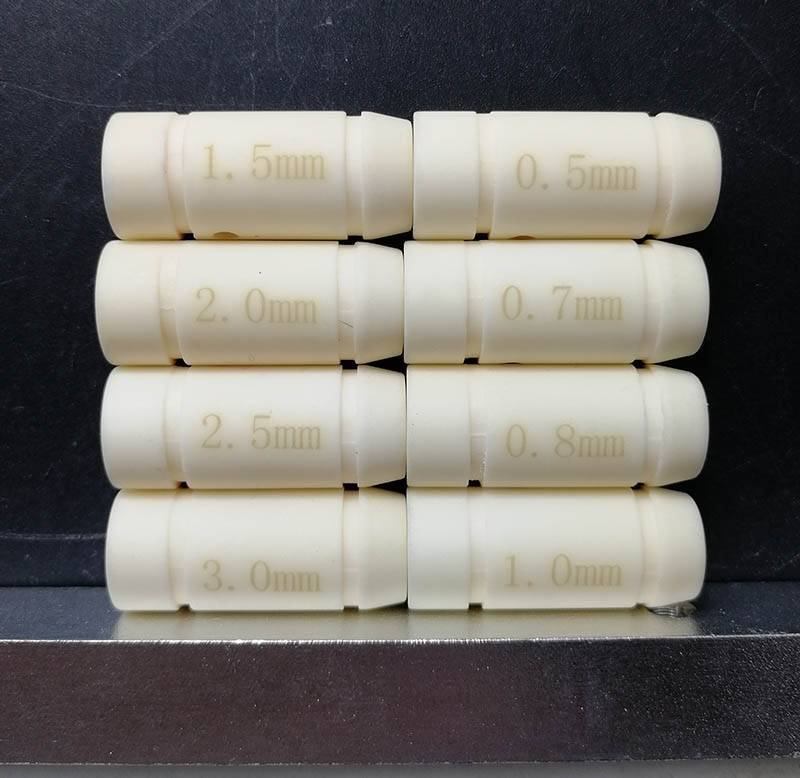

| Focus | -2 | 0 | +2 | Adjust for sharpness. '0' is optimal focus. |

| No. of Passes | 1 | 3 | 5+ | Multiple passes for deeper marks. |

CO2 lasers operate at a wavelength of 10.6 µm, which is absorbed differently by various ceramics.

They are often used when the desired marking effect is a color change without removing material.

They are especially useful for glaze-coated ceramics and can produce a contrasting mark by modifying the glaze.

| arameter | Low Setting | Medium Setting | High Setting | Notes |

|---|---|---|---|---|

| Power (Watts) | 10W | 30W | 60W+ | Adjust based on desired mark depth. |

| Speed (mm/s) | 100 | 300 | 700 | Slower speeds for darker, deeper marks. |

| Pulse Frequency (Hz) | 1k | 5k | 25k | Adjust for mark clarity and depth. |

| Pulse Duration (µs) | 200 | 500 | 1000 | Longer pulses for darker marks. |

| Hatch Distance (mm) | 0.02 | 0.1 | 0.2 | Affects the spacing between marking lines. |

| Air Assist (psi) | 10 | 20 | 30 | Helps in clearing debris and cooling. |

| No. of Passes | 1 | 3 | 5+ | Multiple passes might be needed for depth. |

UV lasers, typically operating around 355 nm, can achieve a "cold" marking process.

This means they can create high-contrast, detailed marks without producing much heat, which reduces the risk of material damage.

They are suitable for delicate or thin ceramics where minimal thermal impact is crucial.

| Parameter | Low Setting | Medium Setting | High Setting | Notes |

|---|---|---|---|---|

| Power (Watts) | 1W | 3W | 5W+ | Higher power may produce darker marks. |

| Speed (mm/s) | 50 | 200 | 500 | Slower speeds for clearer, deeper marks. |

| Pulse Frequency (kHz) | 10 | 20 | 40 | Higher frequency might provide smoother marks |

| Pulse Duration (ns) | 10 | 15 | 20 | Shorter pulses for fine details. |

| Hatch Distance (mm) | 0.01 | 0.03 | 0.05 | Affects the spacing between marking lines. |

| No. of Passes | 1 | 3 | 5+ | Multiple passes for more pronounced marks. |

Marking Effect: Do you want to remove material, or is a color change sufficient?

Material Thickness and Sensitivity: Delicate ceramics might benefit from a "cold" marking process with UV lasers.

Processing Speed: Fiber lasers typically offer faster marking speeds.

Cost: The price point might be a determinant. Fiber lasers are more common and can be more cost-effective for general marking purposes, while UV lasers tend to be more expensive.

In practice, if you're considering purchasing a laser marking system for ceramics or outsourcing the marking process, it's beneficial to test different lasers on the specific ceramic material you'll be using. This ensures optimal marking quality and efficiency.