Latest Blog

What are the applications of high-power UV laser cutting glass?

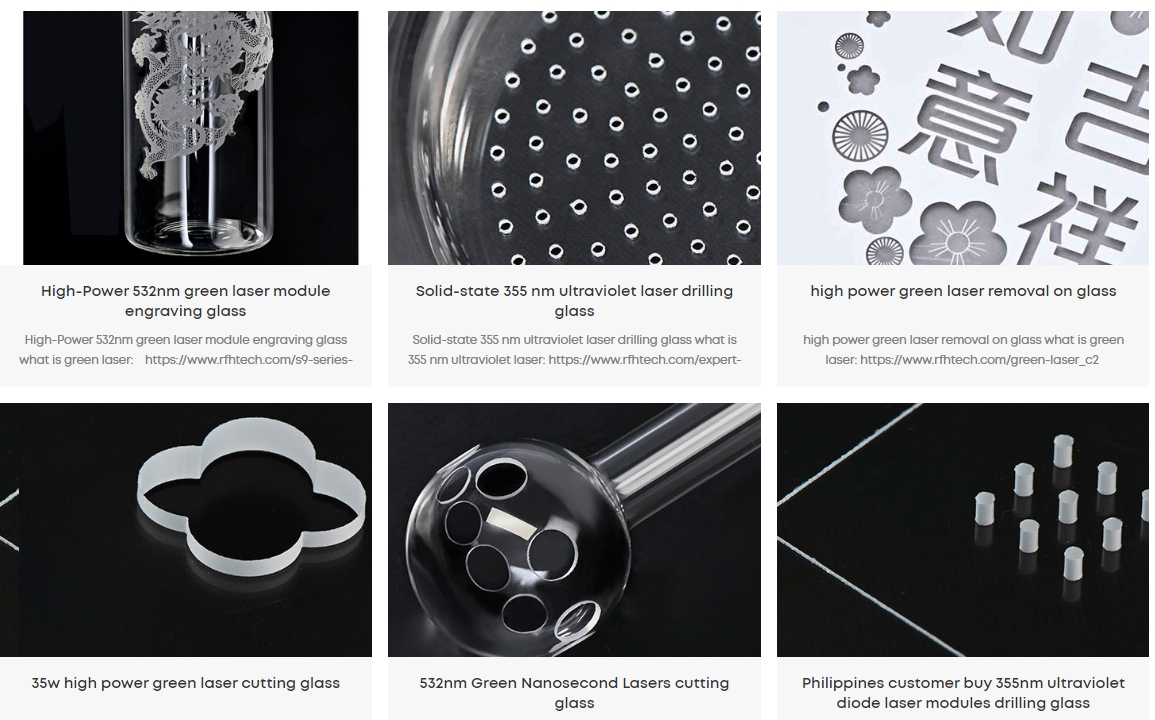

Oct 12 , 2023High-power UV laser cutting glass is attracting attention in the industry because of its high precision, low damage and high efficiency. Applications include: microelectronics manufacturing, solar panel manufacturing, medical equipment, precision instruments, art and decoration, automotive industry, construction sector, fiber optic communications, research and development. Compared with other methods, the heat-affected zone is small, and the cutting accuracy and repeatability of glass are high.

UV laser cutting glass offers several advantages that make it ideal for many applications. Here are the main advantages of UV laser cutting glass:

UV laser has a non-thermal action, which means that it cuts glass through opto-magnetic action rather than thermal action. This minimizes the heat-affected area, preventing the glass from melting, deforming or creating thermal stress.

UV lasers provide extremely high cutting accuracy, which is especially important for applications that require precise size and shape.

UV laser cutting is a non-contact process, which means there is no mechanical stress and wear during the cutting process, ensuring the integrity and smoothness of the glass surface.

UV lasers can cut complex or tiny shapes more easily than mechanical cutting methods.

The UV laser cutting process produces almost no material loss, maximizing material utilization.

Since the edges produced during the cutting process are already very smooth and precise, additional grinding or sanding is usually not required.

Compared to traditional glass cutting methods, UV lasers produce cleaner, crack-free cut edges.

UV lasers can cut various types of glass, including tempered glass, thin glass, composite materials, etc., which may be difficult to process with traditional methods.

The laser power required to cut glass depends on several factors, including the type of glass, thickness, cutting speed, desired cut quality, and the wavelength of the laser. Here are some basic considerations and general guidelines:

| Glass Type: Different glass types have different absorption properties. For example, some glasses may have higher absorption of ultraviolet laser light, while other glasses may be more sensitive to infrared laser light. | Glass thickness: Generally, cutting thicker glass requires higher laser power. |

| Cutting speed: If you want to cut at a faster speed, you usually need higher laser power. | Wavelength of the laser: UV lasers generally absorb better on glass and therefore may require less power than infrared lasers. |

| Cut quality: If higher quality cuts are required, fine-tuning of laser parameters, including laser power, may be required. |

Generally speaking, for common thin glasses, such as 1mm thick standard glass sheets, 5 watts of UV laser power may be sufficient. But for thicker or special types of glass, you may need to use a 20-watt UV laser or even a higher-power 35w green laser

RFH F9 series 5w UV laser: https://www.rfhtech.com/f9-355-series-uv-laser_c17

RFH Expert III 355 series 20 w UV laser: https://www.rfhtech.com/expert-iii-355-ultra-stable-nanosecond-uv-laser-10w-12w-15w-20w_p13.html

RFH Expert III 532 series 35w green laser: https://www.rfhtech.com/expert-iii-532nm-green-laser_c10

High-power UV lasers cut glass with very high precision and repeatability. It provides a smaller heat-affected zone than other methods, meaning the area around the glass is less likely to be damaged by heat. In addition, UV lasers are capable of cutting many high-strength or specialty types of glass that are difficult to process with traditional methods.