Latest Blog

UV Laser Marking Machine on Glass Surface for Frosting Process

Nov 28 , 2022

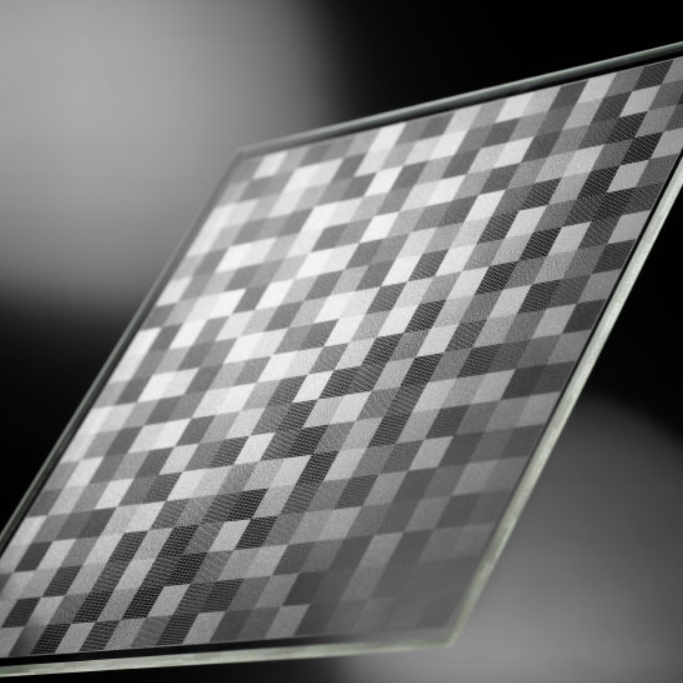

After the glass product is formed, due to some privacy considerations or decorative requirements, the surface of the glass needs to be hazy and frosted, so that the light will diffuse uniformly after passing through the glass and reduce the light transmittance of the glass. Traditional frosting treatment processes include: high-pressure spray gun spraying process, hydrofluoric acid chemical corrosion process, etc. Here is a new glass frosting treatment equipment – laser marking machine.

Laser frosted glass process is using a UV laser marking machine. The smooth glass surface is irradiated with a high-energy laser beam to vaporize to form a texturing effect, thereby improving surface roughness and reducing light transmittance effect. The frosted glass processed by the ultraviolet laser marking machine has a shallow depth of processing area, low glass strength attenuation, and beautiful effect. It is a high-quality choice in the glass frosting process.

| Laser frosting | High-pressure spray gun frosting | Hydrofluoric acid chemical corrosion frosting | |

|---|---|---|---|

| Steps | The operation is simple, the software performs related settings, and the machine automatically completes | Filled with emery and sprayed by high-pressure spray gun, the process is relatively simple | Hydrofluoric acid is applied to the glass surface, suitable for frosting the whole surface, and the steps of partial frosting are cumbersome |

| Cost | The cost is low – the equipment purchase cost in the early stage, and there is basically no cost in the later stage | High cost, high purchase cost of emery | Average cost |

| Safety | High | There are security risks | High risk, easy to damage the body |

Glass laser frosting sample: https://www.rfhtech.com/engraving-glass_nc11

what is uv laser: https://www.rfhtech.com/expert-iii-355-ultra-stable-nanosecond-uv-laser-10w12w15w_p13.html