Latest Blog

UV Laser: Mark Virtually Anything-Full Spectrum Laser

Mar 29 , 2023When it comes to using laser cutters and engravers, there are always going to be limitations with some materials. For example, with the CO2 laser systems, you are not able to work with metals. This is due to the specific wavelengths required to mark, engrave, or cut metals that the CO2 lasers are unable to produce. In order to work with the metals, you’ll need something with a smaller wavelength, such as a fiber laser. The wavelength of a fiber is perfect for engraving and marking metals, but it will not have the same effect on the woods and plastics that you may use, so you’ll still need a CO2 laser in order to engrave those.

It may get frustrating when you realize you need to have a fiber laser system to mark and engrave on metals, but then you’ll also need a CO2 laser system to mark and engrave on plastics and wood. But what if there was another solution? What if there was a laser option that could mark on virtually anything?

Enter the UV Laser.

UV Laser systems, like the Muse UV Galvo, have an even smaller wavelength than a fiber laser, allowing them to mark on most materials. Compared to the fiber lasers and the CO2 lasers, you aren’t limited to a smaller spectrum of materials that you can work with. Instead, if you have a material that you need to mark with your laser, the UV laser will likely be able to leave its mark.

There are so many different types of plastics and polycarbonates out there that it can be daunting to try and remember what you CAN use with a laser, and what you CANNOT use with a laser. There are some plastics that work, but produce toxic fumes, and there are others that will just melt to nothing and give you horrible results. Luckily, many of these restrictions are lifted when you are using a UV laser.

The way UV laser systems like the Muse UV Galvo mark materials, you only get a small fraction of the fumes produced when compared to the fiber lasers and CO2 lasers. This is because the UV lasers create their marks on the material via ablation instead of removing material through melting. So when it comes to marking plastics with the UV laser, your options are pretty much endless. Still, you should be cautious of any fumes that are generated, and safety should always be your number one priority when working with lasers. Even with the UV lasers, it is always best to check the material safety data sheets (MSDS) for that specific plastic, which you can request from the company that either sells or produces the material.

Organic materials refers to naturally occurring materials such as wood, leather, and paper. These materials work great in the CO2 laser systems, but when it comes to the fiber lasers, they don’t have the proper wavelength to be able to work with it. The UV laser systems are able to mark, and sometimes even cut, most naturally occurring organic materials with ease.

The UV laser has a spot size that is significantly smaller than that of a CO2 laser system. Because of this, the UV laser can produce very fine details on organic materials. And with slight adjustments to the frequency, they even have the ability to “bleach” cardboard and paper.

One of the most amazing materials to use with a UV laser system is medium-density fiberboard, or more commonly known as MDF. The nature of MDF allows the UV laser to not just mark, but make incredibly detailed engravings in the material, and even the ability to cut the material. When comparing the cutting results from the UV laser to the CO2 laser, the UV laser produces a much cleaner cut that has much less charring. As always pay attention to safety when working with material like MDF.

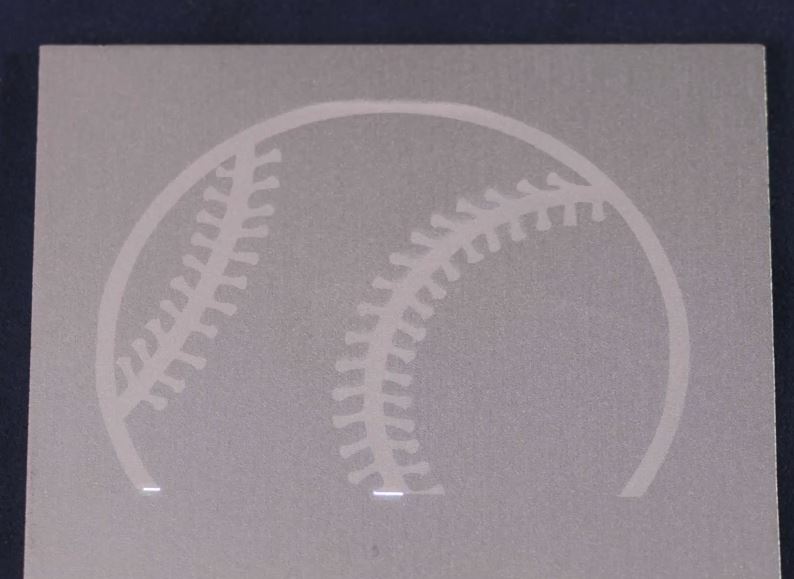

CO2 laser systems are widely used to engrave glass. This is a very common customization that many specialty gift shops utilize, especially when paired with a rotary device. Though, the UV laser systems can produce a much more detailed and higher-contrasting engraving than even the CO2 laser is capable of producing. While this may be one of the more advanced engraving techniques that the UV laser system can be used to produce, the results are stunning.

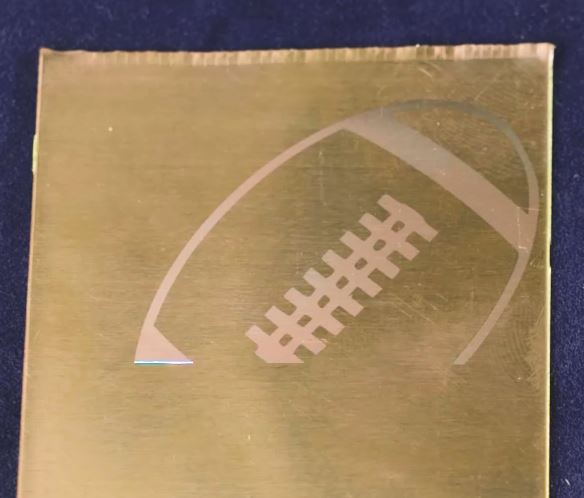

UV laser systems can leave very detailed markings on most metals. Common metals such as copper, brass, and stainless steel are just a few examples of what the systems are able to mark. Due to the wavelength of the CO2 laser systems, they don’t leave any kind of marking on metals, and usually one would have to resort to a fiber system in order to mark and engrave them. Not only does the UV laser system mark organic materials and plastics that the fiber laser cannot mark, but it also marks the metals that the CO2 lasers cannot mark.

![]()

If you have ever worked with silicone in a CO2 or Fiber laser, you’ll understand the frustration that can occur with finding the right settings to produce a nice clean result. This is another area where the UV lasers show their versatility. You can easily mark silicone with the UV laser systems, producing high-contrasting details with precision.