Latest Blog

RFH 355nm Solid State UV laser solves the problem of laser cutting and drilling of optical glass

Feb 10 , 2023RFH 355nm Solid State UV laser solves the problem of laser cutting and drilling of optical glass

Last week, a customer from an optical glass laser cutting and drilling factory placed an order for a batch of RFH 355 series water-cooled Solid State UV lasers.

Today, let's talk about a special kind of glass - optical glass. Optical glass is a glass material used to manufacture lenses, prisms, mirrors, windows and other components of optical instruments or mechanical systems, and it is a key component. The manufacturing standards of optical glass are very strict. Some of its parameters, such as the refractive index value, must be strictly guaranteed to be within the design tolerance range, otherwise it will be a waste product. So, how is such a high-standard special glass made? Next, listen to RFH tell you carefully.

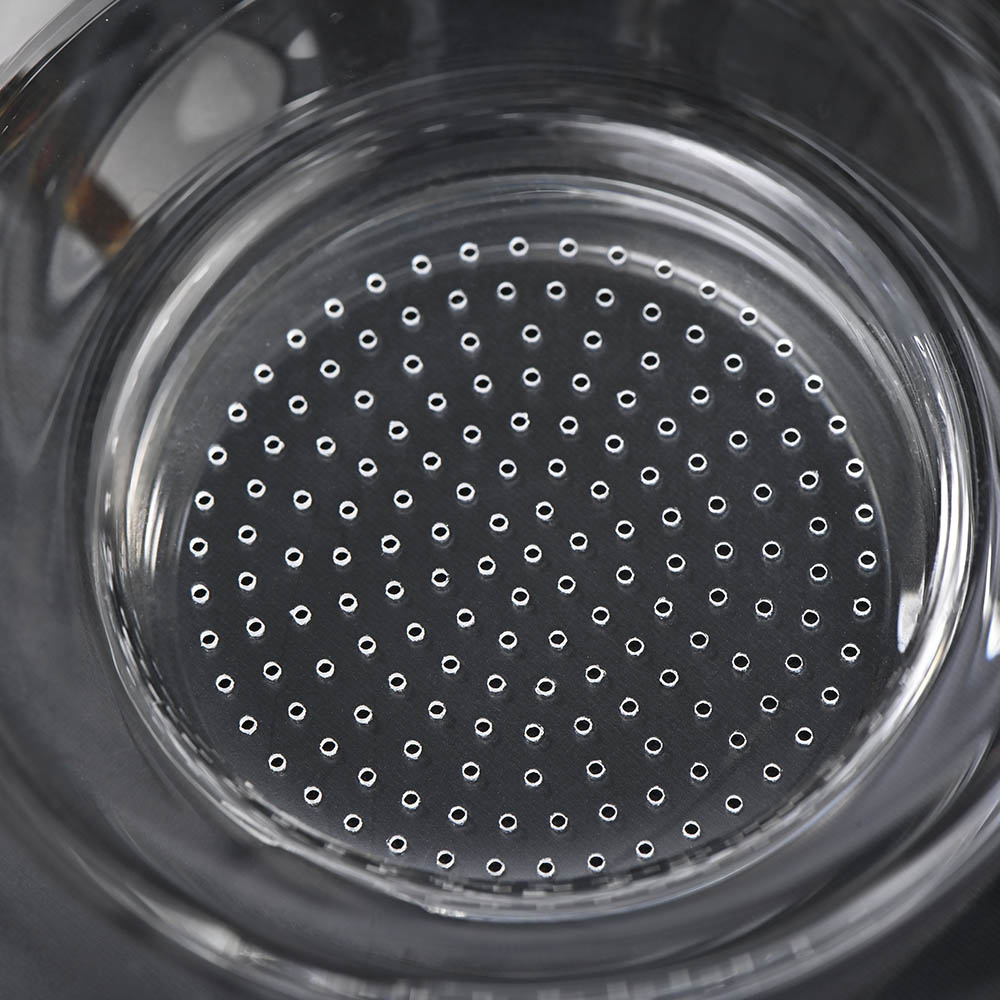

Solid-state 355 nm ultraviolet laser drilling glass

First of all, the raw materials of optical glass mass-produced in the general industry are all in one piece. It needs to be cut, punched, etc. according to the shape requirements of the design first, and then finished and coated. So how are these thin and brittle glasses cut? At first, the precision CNC spindle cutter was used for cutting, but the quality was difficult to control, and the yield rate was far below the expected value. Later, more sophisticated lasers came out, which solved the problem and realized batch processing.

3d glass etching with UV laser cold source

At present, there are two main types of lasers used in optical glass cutting and drilling, ultraviolet lasers and green lasers. Next, take a laser cutting machine that uses our RFH 355 series water-cooled Solid State UV laser as an example to explain why Solid State UV laser cutting machines can become mainstream optical glass cutting and drilling processing equipment.

1. This 355 series water-cooled ultraviolet laser has a laser wavelength of 354.7nm, a wide repetition rate coverage (single pulse to 200kHz), excellent beam quality (M2<1.2), and is strictly guaranteed in all frequency ranges; pulse The width is <16ns@40k, and the heat-affected zone is very small during processing. Such laser beam quality can ensure the processing quality of optical glass: narrow incision, smooth cutting edge, small edge chipping, and fast processing speed, which is suitable for enterprises to carry out mass production. Processing and production; 2. It has a unique Q-switching control technology, which is suitable for various laser application control requirements; it contains online refresh harmonic control technology, and the power stability time is super long, so you don’t have to worry about performance degradation after a period of time. This is also the choice of many manufacturers. One reason to use our laser; 3. Will it be difficult to operate such a precise laser? Not so, in fact its operation is very simple, it supports communication with the computer, and the laser can be controlled externally through RS232; at the same time, it adopts all-digital intelligent power control technology, and the monitoring is also very convenient.

How did RFH make such a first-class quality laser? This is about our R&D team and production management system. RFH has a top-level laser research and development team composed of professors and doctors from Tsinghua University, and has set up application process research and development departments, laser research and development departments, and electrical research and development departments, which are the solid backing for the stable operation of RFH's entire laser system; Management system, we have invested a huge amount of money to build a full-process dust-free production workshop, and the quality control department strictly controls the incoming materials, production, machine acceptance, and shipment to ensure product performance and quality. Because of this, RFH has won high recognition and a good reputation from users from all walks of life at home and abroad.

After 16years of hard work, RFH Laser has established an excellent brand image in the nanosecond laser industry.