Latest Blog

Realization of the First Continuous-Wave Deep-UV Laser Diode Laser

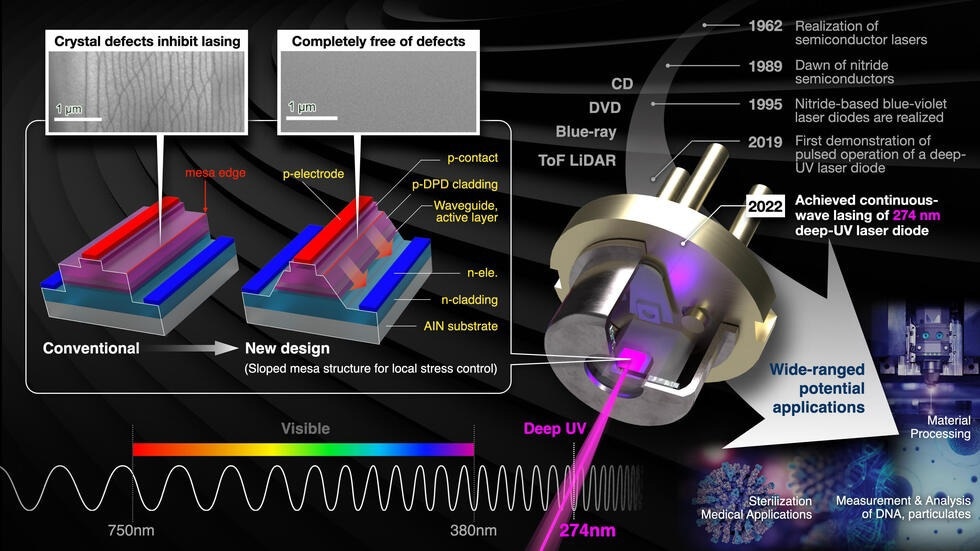

Jun 13 , 2023The world’s first room-temperature continuous-wave lasing of a deep-ultraviolet laser diode (wavelengths down to UV-C region) was completed by a research team at Nagoya University’s Institute of Materials and Systems for Sustainability (IMaSS) in central Japan, under the direction of 2014 Nobel laureate Hiroshi Amano.

Image Credit: Nagoya University

These findings, which were published in the journal Applied Physics Letters, mark an important step toward the widespread adoption of technology with the potential for numerous uses, such as sterilization and medicine.

After decades of research and development since their introduction in the 1960s, laser diodes (LDs) have finally been successfully commercialized for a variety of applications with wavelengths ranging from infrared to blue-violet. Examples of this technology include blue-ray discs that use ultraviolet LDs and optical communications devices with infrared LDs.

However, nobody was able to create deep ultraviolet LDs despite the efforts of research teams from all over the world. After 2007, technology for creating aluminum nitride (AlN) substrates, the perfect material for growing aluminum gallium nitride (AlGaN) film for UV light-emitting devices, emerged.

2017 saw the start of the development of a deep-ultraviolet LD by Professor Amano’s research team in collaboration with Asahi Kasei, the supplier of 2-inch AlN substrates. The development of UV-C laser diodes was initially hampered by the inability to inject sufficient current into the device.

But in 2019, the research team used a polarization-induced doping technique to successfully solve this issue. They created an ultraviolet-visible (UV-C) LD that uses brief current pulses for the first time.

Although these current pulses only needed 5.2 W of input power. Because of the power, the diode would quickly heat up and stop lasing, making this too high for continuous-wave lasing.

The device’s structure has now been altered by scientists from Nagoya University and Asahi Kasei, which has decreased the drive power required for the laser to operate at only 1.1W at room temperature. Since earlier devices could not create efficient current paths due to crystal defects that happened at the laser stripe, it was discovered that they needed a lot of power to operate.

However, the researchers discovered that the strong crystal strain is what causes these flaws in this study. They successfully suppressed the defects, achieving effective current flow to the active region of the laser diode and lowering the operating power through clever tailoring of the side walls of the laser stripe.

The Center for Integrated Research of Future Electronics, Transformative Electronics Facilities (C-TEFs), an industry-academic collaboration platform at Nagoya University, enabled the creation of the novel UV laser technology.

C-TEFs give researchers from Asahi Kasei access to cutting-edge facilities on the Nagoya University campus, giving them the people and resources they need to create dependable, high-quality devices.

Ziyi Zhang, a member of the research team, got involved in the project’s start while still a second-year student at Asahi Kasei.

This study marks a turning point in the practical use and advancement of semiconductor lasers across the entire spectrum of wavelengths. In the future, UV-C LDs might be used in high-definition laser processing, virus detection, particulate measurement, and gas analysis.

Zhang added, “Its application to sterilization technology could be groundbreaking. Unlike the current LED sterilization methods, which are time-inefficient, lasers can disinfect large areas in a short time and over long distances.”

For surgeons and nurses who require sterile operating rooms and tap water, this technology could be incredibly beneficial.

RFH high power uv laser drill circle QR codes on stainless steel

Expert III 355 series UV DPSS laser, developed and produced by RFH, covers 10w-15w in laser power with short pulse width (<20ns@40K) ,superior beam quality (M²<1.2) and perfect laser spot quality (beam circularity >90%). It is widely used in PE/PCB/FPC cutting, glass & sapphire cutting, drilling, scribing & cutting used in high precision micromaching areas.