Latest Blog

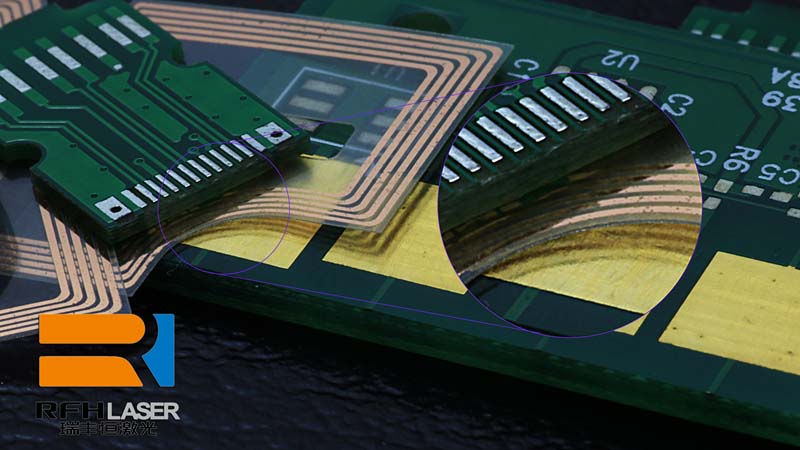

PCB Laser Depanelizing Using a high power UV Laser source 355nm

Feb 06 , 2023PCB Laser Depanelizing Using a high power UV Laser source

One of the methods gaining in popularity for singulating rigid/flex, rigid and flex circuit

boards post assembly is through the use of laser routing. This method has the

advantage of speed, positional accuracy, no tooling wear and lastly no induced

mechanical stresses on components during the singulating process.

There are several cases where laser routing of printed circuit boards is desirable:

o when a high degree of precision of the final assembly is required (think

“tight fit” of a board in to an assembly) or

o when numerous materials need to be cut through and the number and

type of depanelizing steps is to be limited (think “not compromising

cutting one material by using a technique that does not work well on a

second or third material”) or when

o unusual board shapes come up in a design or finally when

o highly sensitive components are placed near the cut out lines of the PCB

need to be treated gingerly.

There are a variety of depaneling options available for PCBs, each with its

own set of advantages and disadvantages.

PCB Depaneling Options

The methods for straight line PCB singulating, which are set up for rectangular-shaped

PCBs, all cut or crush the edge of the board edge. These methods include die cutting,

punching or V-scoring the assembly or by using a wheel cutter or a saw.

The sawing method typically uses a single rotating blade spinning at high RPM to cut

the panel into the shapes required. This method produces heat in the cut out area as

well as creating debris as a byproduct of the cutting operation.

In V-scoring the depth of the thickness of the board is 30-40% of the original board

thickness as it is cut from both sides of the board. After assembly the board is broken

at this v-score line. Alternately a “pizza cutter” cuts through the V-score of the panel

and cuts the remaining web until the boards are in their final cutout shape thereby

putting strain on the components and solder joints-especially those near the board

edge.

In another method, the singulated board outline can be punched out form the panel.

This requires that a new punch be used for every single type of circuit board which

means it is not a flexible method of board cut out. The punch force can also bend or

deform the edges of the PCB. Sharp edges of a well-maintained die must be the norm

in order to get a defect-free cutout.

In board routing and subsequent “nibbling” on a board outline can also be

cut out. Boards are routed prior to assembly. The remaining attached

points are drilled with a small drill thereby making it easier to break

the boards out from the panel post board assembly. This leaves socalled “mouse bite” patterns behind. The routing takes up panel space

as there are keep out requirements around the edge of the board cut

out area. The routing can also reduce panel stiffness which is typically

required and desire during the initial stages of the PCB assembly

process. The advantage the routing process is that curved and nonlinear line patterns can be cut using the router bit.

In each of the above techniques, all of which are mechanical in nature, the board

edges, parts near the cut out area as well as the solder joints will have a high degree of

stress placed on them during the cutting process. This stress may cause delamination of

the board near its edges or develop space in and round the glass fibers near the board

edge. Both of these anomalies may lead to moisture ingress in to the board which may

lead to reliability problems down the road. These potential problems enlarge the “keep

out” areas of the components along the periphery of the boards.

Laser Machining Options

There are several methods by which laser machining can be used to create the board

cutout patterns including perforations, hold-in tabs and scoring. The precision of the

laser cutting source allows for much smaller PCB geometries to be singulated. The

precision of the laser is quite tight especially when compared to other mechanical

methods. The C02 laser sources are positionally and dimensionally within 2 mils (50um)

while the UV sources are within 1 mil (25 um)

Perforations

Similar to scoring or v-grooves, laser perforations are another option for tool-less PCB

removal from a panel. Perforations can be laser formed to any size and spacing to meet

the desired removal and securement forces.

Hold-in Tabs

Hold-in tabs are small uncut sections around the board used to secure the board in the

panel. The hold-in tabs are used due to the ease of handling small parts or part

securement for additional processing. The hold-in tab width is chosen based on the

amount of force desired to remove the individual board from the panel/sheet or known

forces to be applied by downstream processes like component loading or electropolishing. The laser can create tabs in most any material and to any width and location

about the board.

Scoring

Laser scoring produces a limited depth ablation line in the board material or materials.

The depth is generally 50% of the material thickness but can be controlled to a desired

depth. The scoring acts similar to the hold-tab to secure the PCB in to the panel, but

allows for individual parts to be 'snapped' out. Laser scoring lines can also be used as a

deliberate path for stress relief or crack propagation.

How 355nm UV lasers function

UV lasers operating at 355nm are used to ablate or to disintegrate the board material. A

high energy laser pulse vaporizes and removes the top layer explosively turning it into

micro dust particles. This requires that the material, whether it be FR-4, polyimide,

metals or some combination thereof needs to be able to absorb the pulse. The laser

beam goes back and forth over the cut through location ablating a little bit at a time.

This means that because only a small amount of material at a time is vaporized, the

local heating effect is minimized. In fact, measurements taken near the cutting area

(within 1.5 mm of the cut area) show that the temperature rise is well below 1000ͦ Cbelow that of the reflow profile (1). While other shorter wavelength lasers may be more

optimal in terms of performance, their use is limited by their high capital requirements

In order to reduce the cut time and the associated expense the laser beam is “beam

steered” using a galvanometer (galvo). This traces the cutting path in the material over

a small area. This scanner approach arrows the beam to be moved at a very high rate

of speed in the same location over a small area. This speed is in the range from 100 to

1000mm/sec. This makes sure that the beam is in the same area for only a short period

of time thereby minimizing local heating affects.

The fiducials of the board can help determine the relative required location of the beam

cutting location. An X-Y precision table is used for larger mechanical movements and

adjustments while the galvo takes on the micro movements and adjustments of

location.

Conclusion

Laser depaneling of PCBs has its application niche where boards have tight spacing,

where geometric tolerances are critical and where the cutout location lines are very

close to components. The method allows for precise cut out of the boards during the

singulation process with very little heating of the board and very little mechanical stress

compared to traditional board depaneling techniques.