Latest Blog

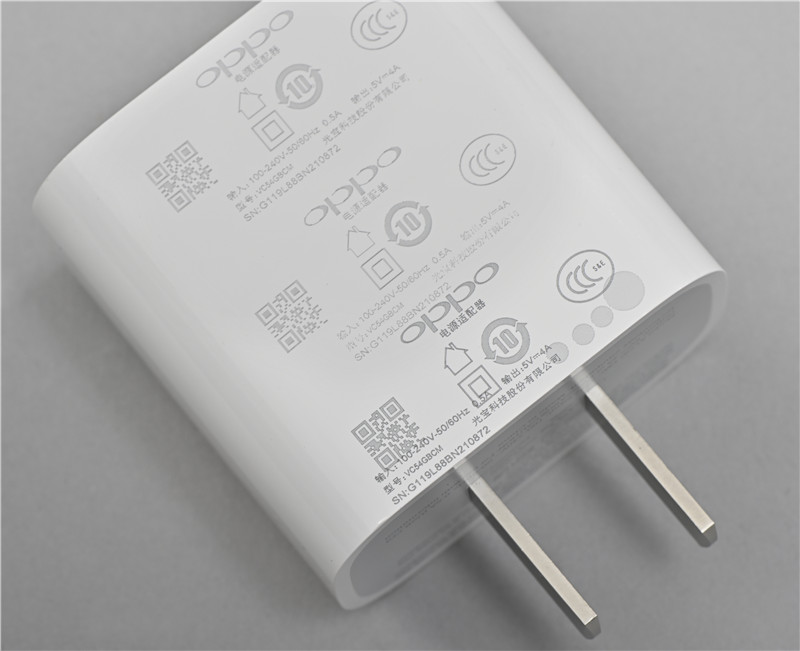

No mold required, 355nm UV nanosecond laser marking plastic electronic plug

Nov 02 , 2022No mold required, 355nm UV nanosecond laser marking plastic electronic plug

As a must-have for power connection, electronic plugs are used in huge quantities in both the household and commercial markets. In order to identify and distinguish, the identification of the date, model and batch of electronic plug production materials has become a necessary and important requirement. In the past, the marking method of electronic plugs was mainly completed by the mold during injection molding, or by coding and labeling. way to achieve.

With the continuous development of laser technology, the reach of laser marking has gradually extended to the field of electronic plug production. Given that the material used for electronic plugs is mainly plastic, a 355nm UV nanosecond laser with "cold" processing characteristics can be an ideal laser marking light source.

"Cold" processing is not really cold, but relative to the 1064nm infrared nanosecond laser, the thermal effect is small, and the heat affected zone is small. Its essence is that the shorter wavelength of 355nm is easier to be absorbed by the material, and the single photon energy is higher, reaching 3.49eV, which can easily break the molecular bonds of some materials. This process is a non-thermal process and is less destructive, so It is called "cold" processing. With the ultra-short pulse width of about 25ns, the heat generated is very small. Therefore, the 355nm ultraviolet nanosecond laser is widely used in heat-sensitive plastics, silica gel, and ceramics, glass, and silicon wafers with hard and brittle properties. , sapphire, etc., and even fine marking on the surface of aluminum alloy and stainless steel layer metal materials, belongs to the versatile laser.

From the point of view of craftsmanship, laser marking easily eliminates traditional craftsmanship from multiple dimensions. Laser marking has no molds, no consumables, no pollution, and is more environmentally friendly. It only needs to set graphics and text through the marking software, and can be marked with optical equipment and a mobile platform, and maintains a very high degree of flexibility. Just move your finger to change it in the background. Moreover, it has excellent beam quality (M2<1.2), and the diameter of the spot after focusing is micron, which is much thinner than a human hair. Not only can it easily mark the date, model, batch and other information, even QR codes, logos, etc. Complicated graphics are not a problem, the edges of the marks are smooth and delicate, the overall contrast is high, and the appearance value increases suddenly. In view of the shortcomings of ink coding or labels that are easy to blur and fall off, the markers marked by laser are permanent and not easy to wear.

In addition, the 355nm ultraviolet nanosecond laser has high stability, can meet the 24*7 production line work, and is not afraid of the temperature and humidity environment, enabling manufacturers to improve quality and efficiency.

355nm ultraviolet nanosecond laser: https://www.rfhtech.com/s9-y-series-integrated-3w-10w-uv-laser_p10.html