Latest Blog

High power green laser cutting PCB/FPC

Aug 03 , 2023High power green laser cutting PCB/FPC

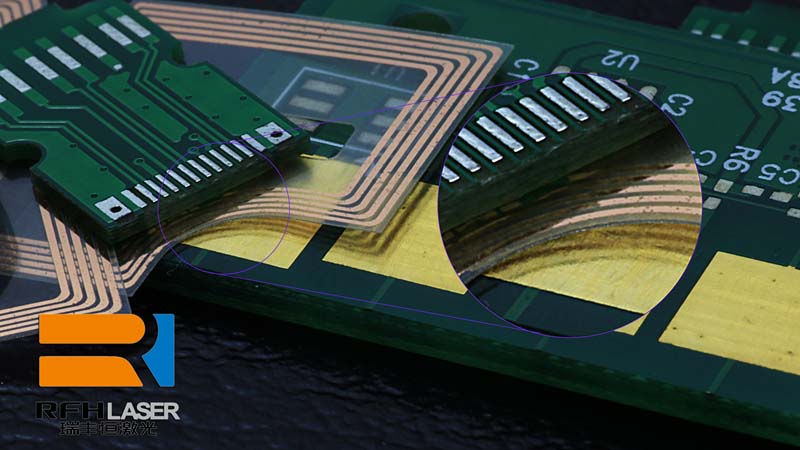

High-power green laser cutting technology is an advanced, efficient and environmentally friendly PCB/FPC manufacturing process. With its unique advantages, such as high precision, fast speed, and small heat-affected zone, this technology is widely used in the field of electronics industry.

First of all, high-power green laser cutting technology has the characteristics of high precision. Its laser beam has a small focused spot, which can achieve high-precision cutting, and is not easy to damage lines and pads. Compared with traditional mechanical cutting, it has higher precision and smoother cutting edges, which can effectively improve the quality and reliability of PCB/FPC.

Secondly, high-power green laser cutting technology has the characteristics of high-speed cutting. Its cutting speed is extremely fast, and it can complete the cutting of a large amount of material in a short time. Moreover, the heat-affected zone is small during the cutting process, which can reduce material deformation and damage, and further improve production efficiency and quality.

In addition, high-power green laser cutting technology also has environmental advantages. A large amount of waste and pollutants will be generated in the traditional cutting process, which will cause serious pollution to the environment. The high-power green laser cutting technology does not need to use chemicals and cooling water, can reduce environmental pollution, and is in line with the current development trend of green manufacturing.

To sum up, high-power green laser cutting technology is an advanced, efficient and environmentally friendly PCB/FPC manufacturing process. Its high-precision, high-speed cutting and environmental protection advantages can greatly improve production efficiency and quality, reduce production costs, and bring a huge impetus to the development of the electronics industry.