Latest Blog

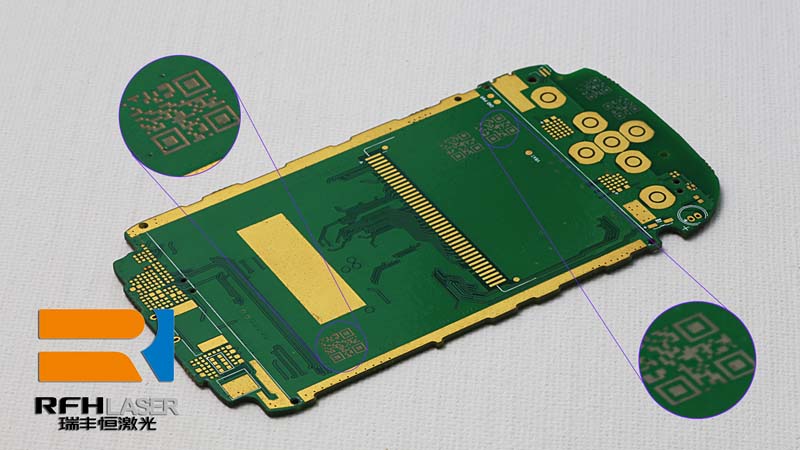

For circuit board engraving, it is better to use green laser or ultraviolet laser.

Oct 12 , 2023

In our daily life, circuit boards are an indispensable part. From home appliances to high-tech equipment, circuit boards play a key role in a variety of electronic products. In the circuit board manufacturing process, laser technology plays an important role. So, for circuit board lasers, which one is better, green laser or ultraviolet laser? This article will combine personal life experience and professional analysis to analyze this issue for you.

UV lasers use laser beams in the ultraviolet wavelength range. In circuit board laser processing, UV lasers can produce high-precision engraving effects with high resolution. Due to the high energy of ultraviolet laser, it can perform in-depth processing of circuit boards and achieve more precise circuit engraving and cutting. Therefore, UV lasers are a good choice for equipment that requires high-precision circuit fabrication.

Under certain circumstances, UV lasers may pose potential hazards to the health of operators. Due to the high energy of UV light, prolonged exposure to UV light may cause skin inflammation, eye damage and other problems. Therefore, strict protective measures must be taken when operating UV lasers.

UV LASER VIDEO

Green lasers use laser beams in the green wavelength range. Compared with UV lasers, green lasers are safer to operate and have less impact on health. Due to the low energy of green laser, its processing depth of circuit boards is relatively shallow, but for some conventional circuit board production, it is enough to meet the requirements.

In summary, for circuit board lasers, green lasers and UV lasers have their own advantages and disadvantages. Which laser is better depends on the specific application scenarios and needs. If you need high-precision circuit production and the operator can accept the ultraviolet laser band come with the potential hazards then UV lasers are the better choice. However, if your requirements for circuit accuracy are not very high and you are more concerned about operational safety and personnel health, then green lasers will be a better choice.

After understanding the characteristics of green lasers and ultraviolet lasers, we can make reasonable choices based on actual needs. No matter which laser is chosen, comprehensive considerations need to be combined with the actual situation to ensure that the manufactured circuit boards can meet the expected requirements while protecting the health and safety of the operators.

Shenzhen RFH Laser Technology Co.,Ltd was founded in 2007 with headquarters in Shenzhen High-Tech Industrial Park, branch offices in Wuhan and Suzhou and production base in Huiyang.

As the leading industrial solid-state laser manufacturer, RFH laser company offer 355nm ultraviolet laser, 532nm green laser and customized laser for a broad range of commercial, industrial, and scientific applications.

After 13 years of development, RFH now has an industrial laser oriented R&D team made up of top professionals and experts from both home and abroad. Its R&D departments cover engineering, laser and electric. In addition, RFH has obtained 15 national patent certificates and 14 software copyright certificates and is certified as “High Tech Enterprise”, “Shenzhen High Tech Enterprise” and “Software Enterprise” as well as the council member of Guangdong 3D Printing Industry Innovation League and Guangdong Laser Industry Association.

Orienting to serve laser end users and system integrators, RHF’s products cover from green laser to deep UV laser whose pulse power, average power and pulse repetition rate are applicable in various laser applications, including consumer electronics, electronics circuit, packaging & printing, solar power, lithium battery, semiconductor microelectronics, panel display, jewelry, biomedicine, automobile and aerospace. RFH lasers are widely used in SLA 3D printing, high precision marking & drilling & cutting, laser welding, laser plastic & metal welding, laser medicine, surface removal, wire stripping and laser inner engraving.

Cooperation brand

RFH has a complete product line and rigorous quality control system. Production is performed in dust-free workshop. Rigorous control by QC department in incoming materials, production, product check & acceptance and delivery guarantees the performance and quality of the product.