Latest Blog

355nm UV laser marks black on cable and wire

Sep 14 , 2023355nm UV laser marks black on cables

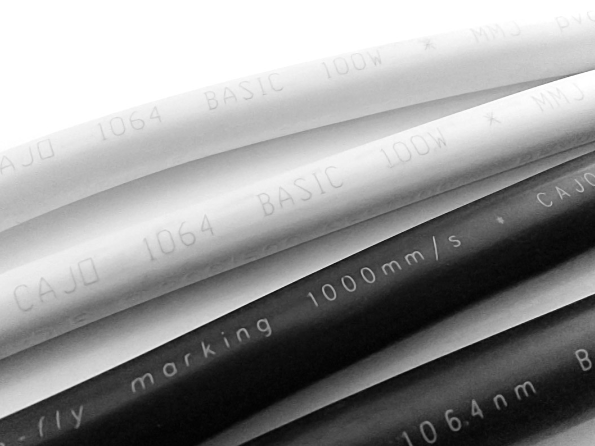

Black printing on cables with 355nm ultraviolet laser is an important process method. It uses laser energy of specific wavelengths to achieve precision processing of cable surface materials. In this process, the laser beam is focused and irradiated on the surface of the cable, causing the material on the surface of the cable to change. This change is mainly achieved through burning, melting, evaporation, etc.

In this process, the use of 355nm UV laser has many advantages. First, due to its special wavelength characteristics, it can perform precise local processing of the cable surface without affecting other surrounding cables or equipment. Secondly, this laser processing method can achieve efficient, high-quality processing, and the processing speed is very fast, which can greatly improve production efficiency. In addition, since laser processing is a non-contact processing method, it can avoid problems that may occur in traditional processing methods, such as tool wear, surface scratches, etc.

There are many purposes for painting black on cables, including beautifying the appearance of the cable, improving the insulation performance of the cable, and enhancing the corrosion resistance of the cable. Through this processing method, a uniform black coating can be formed on the surface of the cable. This coating can not only improve the appearance of the cable, but also effectively prevent oxidation and corrosion on the cable surface. At the same time, the black coating can also improve the insulation performance of the cable, allowing it to maintain excellent performance in high temperature and high pressure environments.

In short, 355nm UV laser to blacken cables is an efficient, precise and high-quality process, which can effectively improve the performance of cables and extend their service life. With the continuous advancement of science and technology, we have reason to believe that this laser processing method will be applied and promoted in more fields.