Latest Blog

15w high power uv laser depaneling for PCBA / EMS

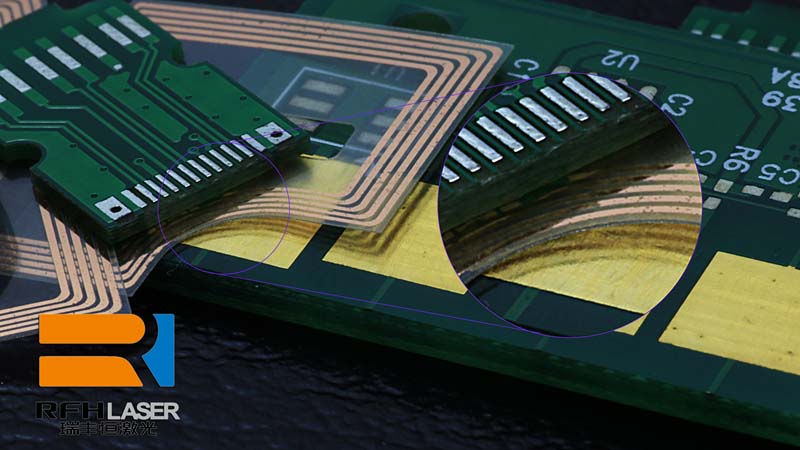

Feb 28 , 202315w high power uv Laser depaneling for PCBA / EMS

Stress-free, clean cutting of populated rigid and flexible PCBs

Circuit reliability is significantly improved and fewer or even no extra cleaning processes are required with laser cutting, which thus offers significant cost savings for laser depaneling. A new family of depaneling systems delivers an unprecedented combination of performance, reliability, and low cost.

Process advantages due to laser technology

Compared with conventional tools, laser processing offers a compelling series of advantages.

The laser process is completely software-controlled. Varying materials or cutting contours are easily taken into account through adaptation of the processing parameters and laser paths. There is no need to factor in retooling times during a change of production.

No appreciable mechanical or thermal stresses occur. Even sensitive substrates can thus be precisely processed.

The laser beam merely requires a few µm as a cutting channel. More components can thus be placed on a panel.

The new LPKF CleanCut technologycreates absolutely clean and distortion-free cutting channels – setting a new benchmark in the depaneling industry.

Stress-free processing

Another advantage of the laser’s non-contact processing principle is the stress-free cutting of the substrates. In contrast to mechanical separation process such as milling, sawing or punching, no mechnical stress is induced into the material. Possible damage to mounted components is thus avoided.